Table of Contents

One of our customers was surprised about the measurement data of the smart memo behind a gas pressure regulator. The customer wondered about fluctuating pressure data that were inexplicably high for him. He was not used to these large fluctuations from measurements with other pressure measuring devices or our GasTest delta at similar measuring sites. Consequently, he wanted to attribute the problems and errors to our measuring device and called us.

We would like to take our customer’s problem as an opportunity to point out some basic aspects of pressure testing and to highlight the subtleties and special features of pressure testing behind a regulator. In particular, we would like to explain the differences between absolute pressure measurement and relative pressure measurement using this example.

You can also read about how a relative pressure sensor and an absolute pressure sensor work in our blog post Sensor principles explained.

Measurements with smart memo and the EDS2-P 1bar on a pipe behind a gas pressure regulator

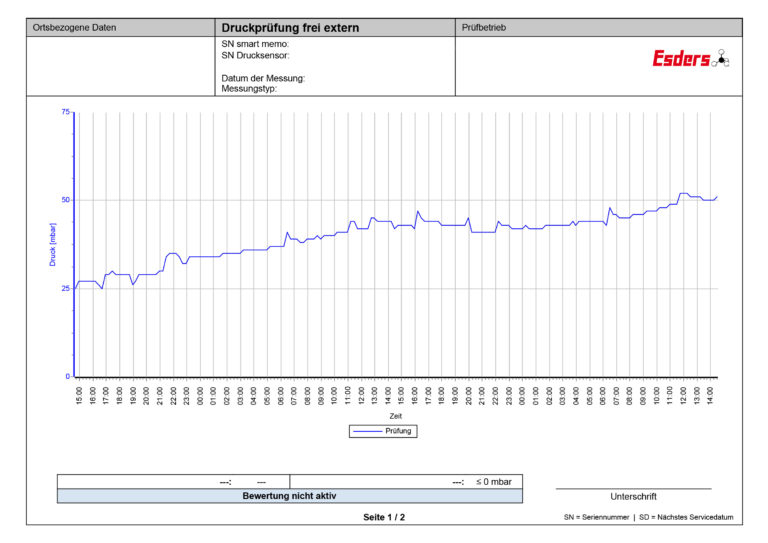

The customer used our smart memo with the EDS2-P 1bar 0.1% to perform a function test of a regulator. The EDS2-P 1bar 0.1% is an absolute pressure sensor with a measuring range of 0-1 bar (overpressure), i.e. it measures absolute pressure values of a pipe system. In this case, the absolute pressure of the pipe system behind a regulator is measured. The customer’s test report looked like this.

Using this measurement site, we now want to explain the course of the measurement data behind a regulator and describe what data our absolute pressure sensor provides.

As a general rule, if you carry out a pressure test behind a regulator, it is important to consider which measurement methods are suitable for the particular purpose of the test.

(A) If the pipe is to be tested for leaks, absolute pressure measurement is usually recommended.

(B) If the functionality of the regulator is to be tested, a pure absolute pressure measurement is out of the question.

A regulator has the function of setting the line pressure to a constant value relative to the atmospheric pressure. This means that as soon as the air pressure rises/falls, the regulator adjusts the line pressure up/down accordingly. This in turn means that the absolute pressure in the line also rises/falls!

To evaluate whether the regulator is working (i.e. regulates to a constant overpressure), it is not the absolute pressure in the pipe that must be considered, but the relative pressure of the pipe (i.e. the overpressure to the air pressure). This relative pressure should be approximately constant.

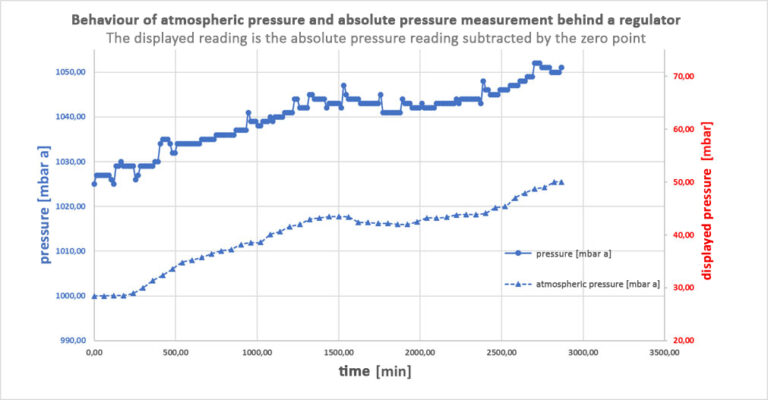

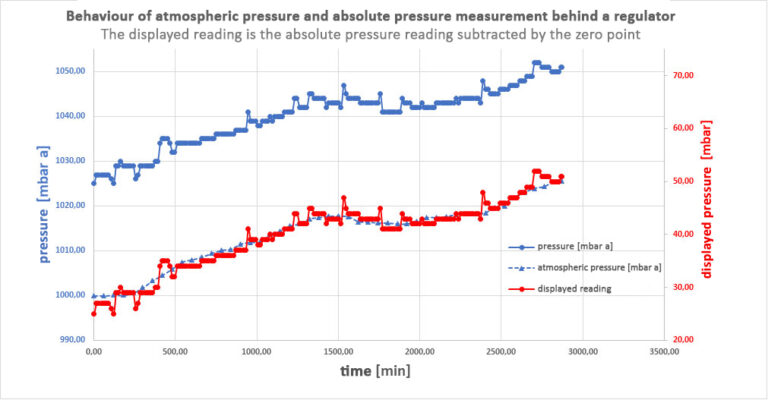

Below you can see the mentioned measurement data of the absolute pressure measurement behind the regulator. As you can see, the absolute pressure is not constant, which is correct for this measuring site. The atmospheric pressure is measured with an internal sensor of the smart memo and recorded. As you can see, atmospheric pressure and absolute pressure readings behave similarly.

A constant value for the atmospheric pressure (usually 1.000 mbar) is generally subtracted from the absolute pressure readings, so that an overpressure compared to the atmospheric pressure is always displayed as the measured value. This results in the data shown in red (right y-scale). The data marked in red is exactly the data that is saved in this case and displayed in the report. They pretty much follow the prevailing atmospheric pressure.

What exactly happens in our smart memo during absolute pressure measurement?

We’ll explain it again with a simple example:

We measure with an absolute pressure sensor that is set to zero before the measurement is started on the prevailing atmospheric pressure. The atmospheric pressure is 1.000 mbar. The line pressure is 23 mbar.

Atmospheric pressure + line pressure = absolute pressure

1.000 mbar + 23 mbar = 1023 mbar

Now the weather changes and, in the course of the measurement, so does the atmospheric pressure. The atmospheric pressure is now at 1.015 mbar. The line pressure remains the same.

1.015 mbar + 23 mbar = 1038 mbar

But because we set the zero point to 1.000 mbar before this measurement, the pressure in the display of the smart memo will now no longer show 23 mbar, but 38 mbar (23+15).

Conclusions regarding the measurement behind a gas pressure regulator

Therefore, the absolute pressure values for this type of measurement (behind the regulator) seem confusing at first. In fact, for a regulator test, the difference between the measured absolute pressure values (blue circles) and the measured atmospheric pressure (blue triangles) must be displayed, i.e. the relative pressure. This measuring method is available with the smart memo and can be selected via the settings of the menu item “Pressure test free external”: “Relative pressure measurement yes”. Here, a constant value is no longer subtracted from the measured absolute pressure (the zero point of 1.000 mbar), but the actual atmospheric pressure, which can change. Thus, the relative pressure set by the regulator is always displayed.

A pure absolute pressure measurement only makes sense at this measuring site if the regulator is removed or bypassed and a leak tightness measurement is carried out to assess the tightness of the entire system.