Table of Contents

With new building and pipe materials, the leak frequency and the quantities of gas escaping are drastically reduced. Therefore the effective pre-location during the systematic pipe network inspection has become even more important. Combined procedures, which work with a focused approach during pre-location and a pragmatic one during pinpointing – deliver results that are both safe and economically efficient. In the future, these procedures might be expanded to include vehicle-based methods and active laser measuring devices for remote detection.

Recommended leak detection technology

The requirements for measurement technology for the systematic inspection of gas pipe networks have changed in Germany. The number of leakage points in the pipe network has rapidly decreased over the last decades. This allows for new combinations in device technology. In the Esders range of devices, the new series of the gas measuring device OLLI offers good possibilities for combining HUNTER and OLLI.

For pre-locating the networks, we recommend the professional device that is optimally and exclusively designed for this task – the HUNTER. With maximum sensitivity, long operating time, appropriate weight and wireless data transfer for easy pairing with a tablet, it meets all the demands of today’s world.

Due to the changed situation, the combination with the explosion-proof gas warning and gas measuring device OLLI is suitable for localisation. The OLLI can be used both as a warning device when entering cavities or structures and for measuring methane up to 100 Vol.% by infrared. The IR sensor also meets the CO₂ measurement requirements of G 465-4. Due to its low weight of approx. 400 g, it can be constantly on the man without difficulty.

When checking gas pipe networks, the work is usually divided into pre-location and then exact containment, i.e. pinpoint localisation.

For pre-location, a gas detector is required in Germany, which displays test gas with 10 ppm methane in synthetic air, within 10 seconds, with a minimum reading of 8 ppm. The inspection must include the probe system used.

This sensitivity check must be carried out both before and at the end of the work each day and must be documented.

German DVGW Worksheet G 465-4

There are also requirements for the devices used to isolate the leaks, which are described in detail in G 465-4.

Essentially, these are the measuring range from 0 to 100 vol.% methane or natural gas and a display and reliable detection of 0.1 vol.% methane. In order to exclude a too strong influence of the display via the carbon dioxide concentrations in the soil, a measurement of carbon dioxide – CO₂ is required.

With the HUNTER, the pipe network inspector has a specialised measuring device for pre-location according to DVGW worksheet G 465-4 at his disposal. We also say: Our professional for pipe network inspection!

It has a very high sensitivity, fast response time and almost no cross-sensitivity to the exhaust gases in road traffic. At the same time, the quality of the sensor technology is so high that very many FID’s (flame ionisation detectors) in the market have been replaced with the HUNTER after intensive comparisons by customers.

This measuring device is used exclusively for the optimal pre-location of leakage points. Elaborate measures for explosion protection have been dispensed with for the device, as they are not required for this activity. This eliminates the need to comply with the severe restrictions, e.g. on the maximum possible amperages and the fusing of the batteries, which are required for explosion protection certification. The advantage of this is that more powerful pump outputs, rechargeable batteries and also current-intensive sensors can be used, which in turn increase the performance of the device. The disadvantages resulting from explosion protection, such as limited operating time, especially if you also want to use wireless data transfer for permanent transmission of the measured value to an external device, therefore do not apply to the HUNTER.

In practice, it often happens that even 8 h of operating time is not enough for the devices of the pipe network inspection. Because when the weather is good, you want to take the opportunity to check as large an area or as many kilometres of pipe as possible. In addition, the employees are often on “assembly” and work out their weekly working hours from Monday to Thursday, then work out an additional day off on Friday. So 10 h operating time and a little reserve are desirable for the daily work routine.

In combination with the explosion-proof gas measuring & warning device OLLI, all work can be carried out during pipe network inspections.

The OLLI is equipped with a dual infrared sensor and can monitor the approach to the lower explosion limit (LEL) as well as be used for measurements of the soil air in probe holes. Methane is displayed with a resolution of 0.1 vol.% up to 100 vol.%, as well as carbon dioxide up to a concentration of 5 vol.%.

If gas is detected in the immediate vicinity of a building or cavity, the OLLI offers the possibility of detecting the smallest gas concentrations in the LEL range with the application area “monitoring of working space”. It displays with a resolution of 0.1% LEL. This corresponds to 44 ppm methane, i.e. approx. 50 ppm methane resolution.

Since natural gas can be perceived olfactorily, i.e. by smell, from approx. 200 ppm, this means that even concentrations that cannot be smelled lead to a reading.

Assessment and classification of leaks

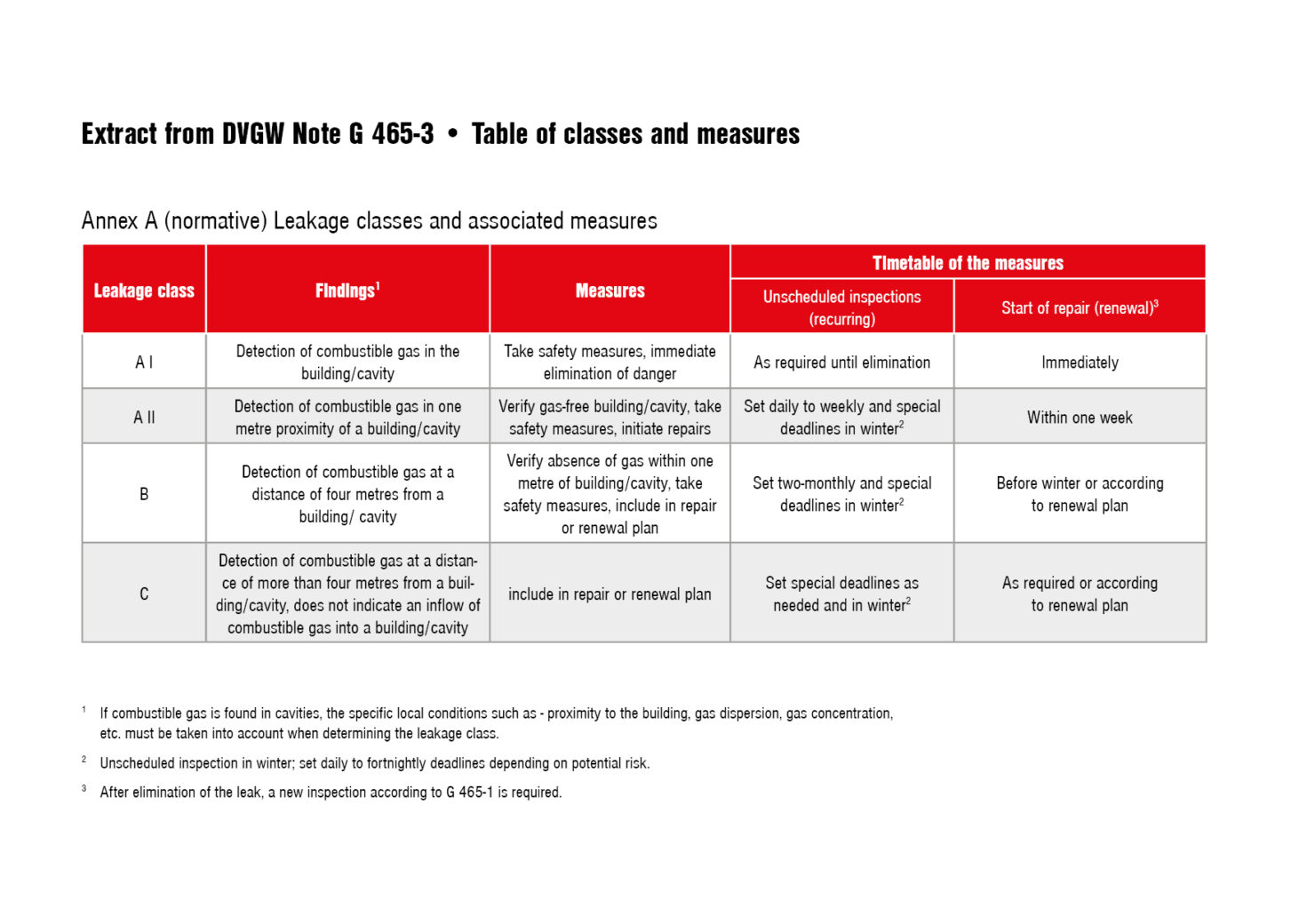

The criteria according to which leaks are to be assessed and classified are stated in DVGW worksheet G 465-3.

The procedure is such that one evaluates a pre-located gas leak in its propagation. Special attention must be paid to cavities such as shafts, ducts and buildings. The distance of a gas detection from a cavity determines the type of classification.

Example

Gas is indicated above ground in the line in front of the building. The mains connection line to the building is also tested and gas is also detected directly in front of the building. An entry of gas into the structure or building cannot be ruled out. The building is checked for gas using an explosion-proof gas detector. The gas detector must assume that dangerous concentrations are possible in the building. To avoid sparking, one tries to gain entry by knocking. The main focus is on gas entering the building from the outside. But the premises must be checked comprehensively and widely for evidence of gas.

If gas is detected in the building, it is an AI (A1) location and the hazard must be eliminated immediately. The network operator’s emergency service will be notified for this purpose.

If no gas is detected in the building, the classification is carried out in front of the building by measuring the soil gas concentration. A borehole probe or gas detection probe is used for this purpose. The probe holes should not exceed a depth of 30 cm. If gas with a concentration of 0.1 vol.% or more is detected directly in front of the building at a distance of max. 1 m, the classification is AII (A2). If gas is detected between 1 and 4 m away, it is a B site. And at a distance of more than 4 m from the cavity or building, it is designated as a C site.

Gas pipe network inspection according to DVGW worksheet G 465

The leakage classes result in measures and fixed deadlines within which these measures must be carried out.

Before a building is entered for further assessment, a direct danger to life and limb must be ruled out by means of a so-called confined space entry measurement. The OLLI’s ability to detect the smallest gas concentrations in the LEL range is also used for this purpose. In addition, the device can also warn of carbon monoxide (CO) if equipped accordingly. For some time now, there has been an intensive public discussion about the dangers of carbon monoxide in order to make people more aware of this issue. There is also frequent talk of so-called CO alarms, which – in addition to smoke alarms – should be permanently installed in flats and houses. CO is an often underestimated gas, as it is colourless and odourless and can have serious health consequences, even death, at low concentrations.

If a hazard has now been ruled out by measuring the room air, the HUNTER can also be used in the building again.

It can then be used to carry out the room air measurement required by DVGW worksheet G 465-1 and to make an assessment as to whether 10 ppm of natural gas in the room air indicates gas ingress.

If the internal parts of the mains connection are also to be checked for leaks according to G 465-1, the HUNTER offers all possibilities with the application area of testing the building, if dangerous concentrations have been excluded in advance with the OLLI.

Thus, the inspections according to G 465-1, which are the responsibility of the network operator, can be carried out completely. This also applies to the main shut-off valve, the gas pressure regulator and its connecting pipe to the main shut-off valve, and the meter screw connection.

For this work, the pump output of the HUNTER is lowered so that there is no excessive dilution of small gas outlets.

Generally, it is important to note that the cause of a gas odour must be found and eliminated. An assessment according to a serviceability test in accordance with DVGW TRGI 2018 is not sufficient!