Table of Contents

What does adjustment mean and what is calibration? What is the difference? What is a bump test? Why do sensors need to be checked regularly?

Gas sensors lose sensitivity in the course of their life. Depending on the operating principle, this varies greatly for the respective sensors used.

The sensors we use in our measuring devices and how they work are covered in detail in our blog post on sensor principles.

What is the calibration of measuring devices?

The comparison of the measuring device’s display with a known test gas concentration (“sensitivity check”).

Calibration of a measuring instrument is about verifying the measurement behaviour in comparison to the normal behaviour. The goal is to determine the deviation of the sensors and to evaluate whether the deviation is still within the limits or whether an adjustment is necessary if the values are outside the limits. The calibration is carried out with the measuring device and the correct test gas.

Example with OLLI:

In the menu item “Calibration/Adjustment”, the measuring device can be calibrated for various applications and adjusted if necessary. The correct test gas can be applied to the sensors several times. Calibration can be carried out without entering the password, adjustment is password protected.

What has to be considered during calibration?

Calibration must be performed in a clean air environment, i.e. the air must be free of hydrocarbons and toxic gases. In addition, there should be no oxygen-deficient or enriched atmosphere.

After selecting this menu item, the sensor run-in phase begins. After the sensor initialisation phase, the zero points appear. These should be stable at zero or at 20.9 vol.% for O2 and at 0.04 vol.% for CO2.

In case of deviations, the zero points can be set manually.

Regular calibration is part of quality assurance.

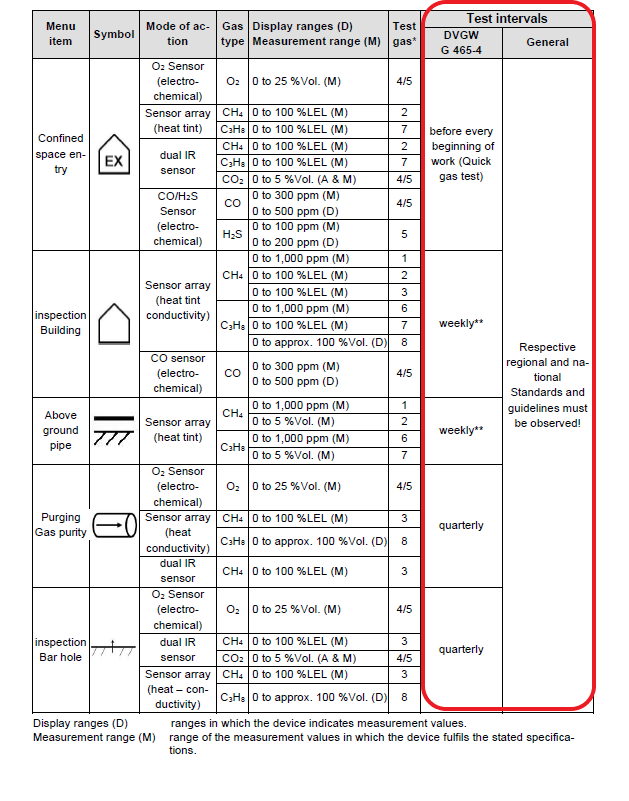

Applications and test intervals - Example with OLLI

What happens if a calibration has failed?

Possible causes for this can be an incorrect test gas or too much or too little test gas during the calibration process. The calibration can be repeated with the correct test gas. It is also possible that the measured value is simply outside the limits. This still has nothing to do with a defect of the device or wrong test gas, but is a normal behaviour. Sensors can wear out over time and in this case the affected sensor must be adjusted.

Another cause may be a defective sensor. The device may need a longer sensor run-in period in clean air or must be returned to the factory for an inspection and, if necessary, repair.

What is the adjustment?

Adjusting the zero point and sensitivity of the measuring device with known zero & test gases (“sensitivity adjustment”).

Adjustment is the intervention by qualified personnel in the settings of the measuring behaviour of a measuring device.

The purpose of the adjustment is to eliminate a deviation in the measurement behaviour to the extent necessary for the required application. In contrast to a calibration, a technical intervention is necessary that changes the entire characteristic curve, i.e. the sensitivity setting of the sensor. That is why in the menu of our measuring instruments, there is always a query as to whether this should be carried out irrevocably, before the adjustment can be made.

Example:

- The OLLI displays 50 ppm in pure air. The zero point is then reset during adjustment.

- The OLLI shows 1.6 vol% methane, but we have added test gas with 2.2 vol% methane. The sensitivity of the sensor is then reset during adjustment.

What is a Bump Test?

The bump test checks whether a gas detector is functioning properly. This includes, for example, checking whether the gas sensor reacts to the target gas. Alarm thresholds are tested to ensure that the sensitivity of the gas detector’s sensors is OK before use.

A bump test is a simple and quick functional check of the device. During the Bump Test of the OLLI, the device is checked for the following: Free flow of the gas paths in the device, reaction of the device to the test gas, intact sensors, alarms (visual, audible and vibration).

In the video, Martin Esders explains the exact procedure of the Bump Test.

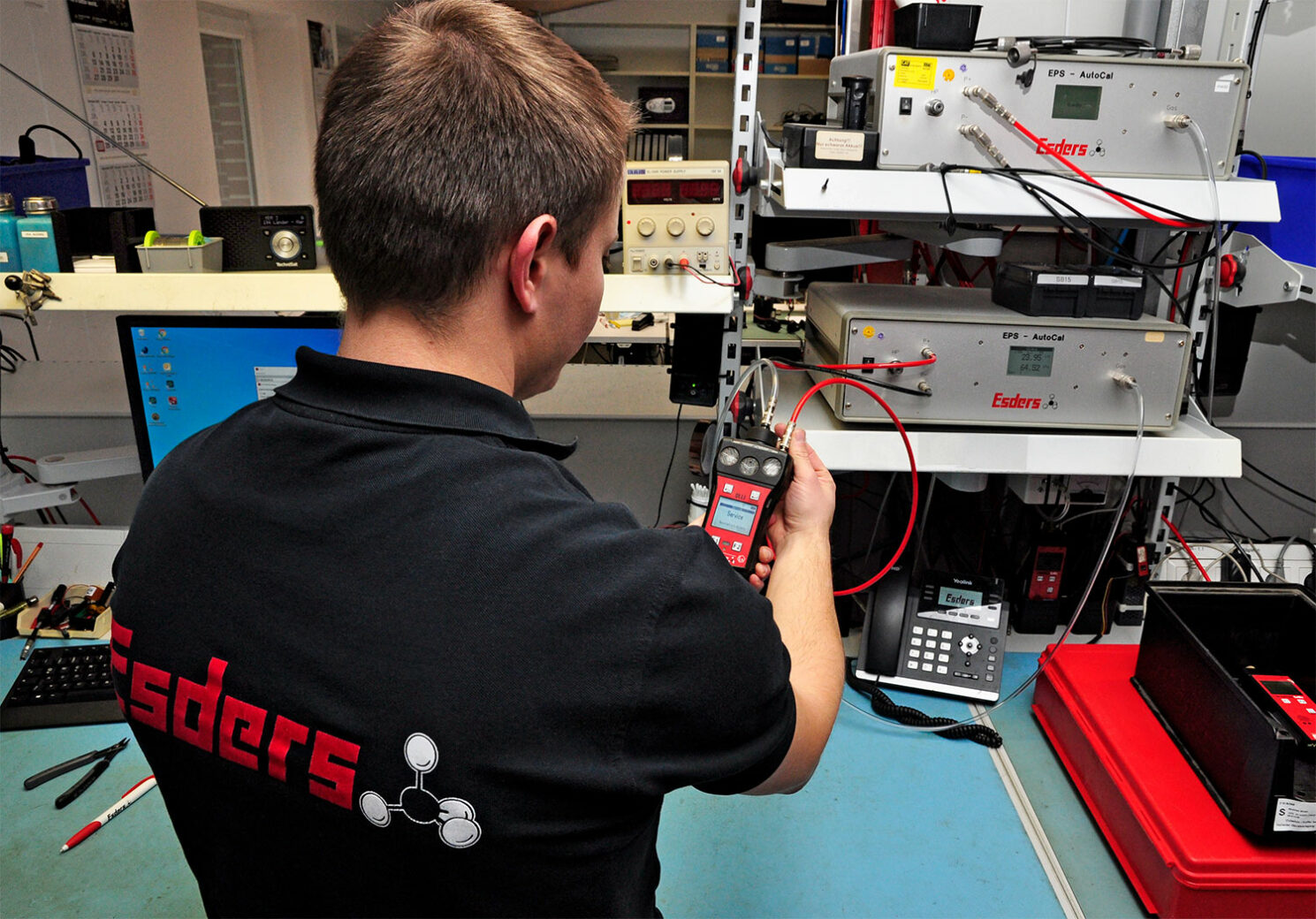

What is the difference to the manufacturer's service / adjustment?

In general, it is important for a safe everyday working life that users are able to carry out a large part of the regular functional checks themselves. Our service as a manufacturer includes a complete check of the measuring device in addition to calibration and adjustment. The actual condition of the system is carefully checked and the target condition is restored. The controls here in Haseluenne also include cleaning and testing of the electronics. The batteries are checked to ensure they are within specification and the pump performance is tested. The filter and accessories are inspected. We take a close look at the sensors and check whether they meet the specification. In individual cases, e.g. runtime-limited sensors are replaced. Once all work has been carefully completed, the test certificate/service certificate and the test badge are renewed.

We currently need 4 days to service your device, from the time it arrives at our factory to the time it is prepared to be shipped back to you. The prerequisite for this is that you plan your service with us. You can do this by phone, by email or simply via our service form. If you are already registered in Esders Connect, you can also easily schedule appointments via the online portal or the app.