Table of Contents

To ensure the long-term security and economic operation of district heating networks, the AGFW (Association of Energy Efficiency Companies for Heating, Cooling and CHP in Germany), has created its own set of rules, worksheet AGFW FW 602, in which the various test procedures for medium pipes to prove tightness and strength are published.

The recommended procedures include, for example, the test with overpressure:

- Differential pressure measurement method

- Pressure measurement method

- Water pressure test

They differ in equipment technology, execution and procedure.

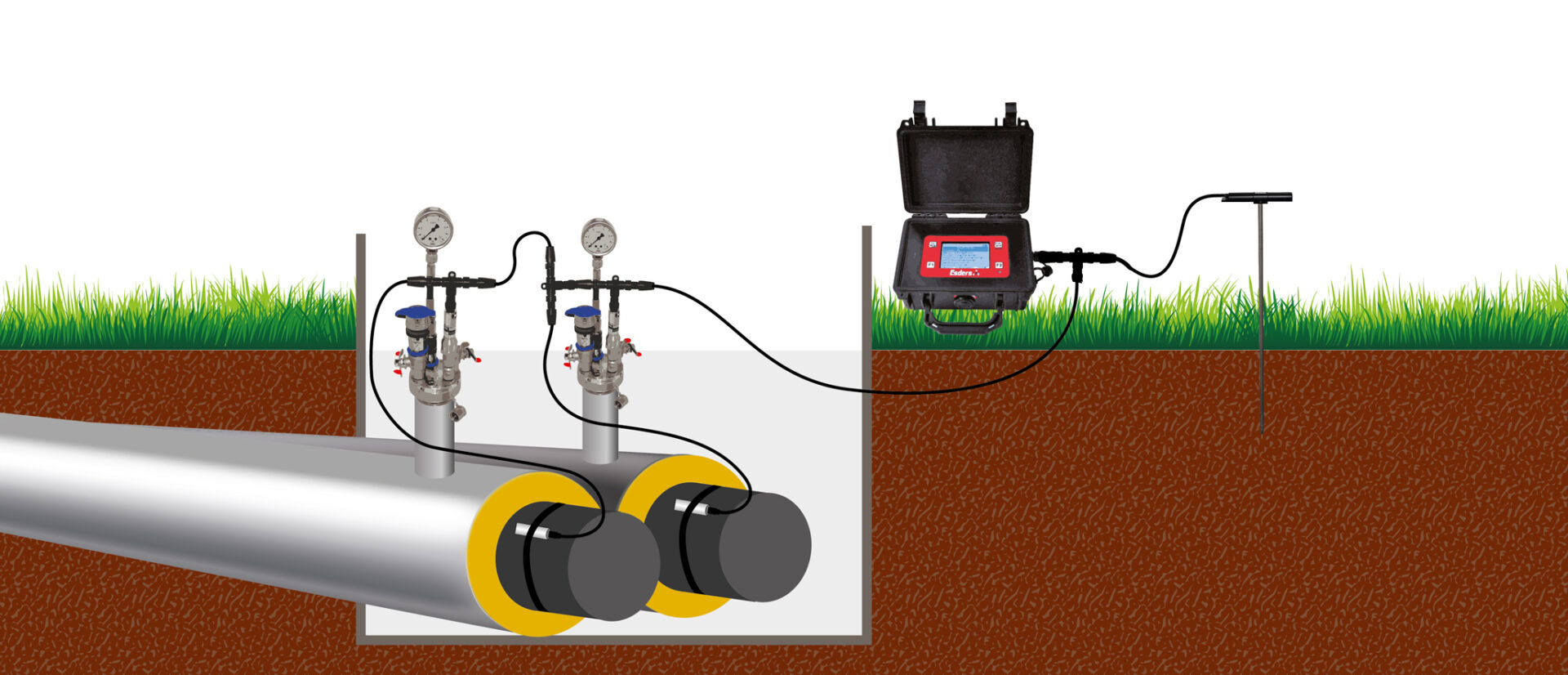

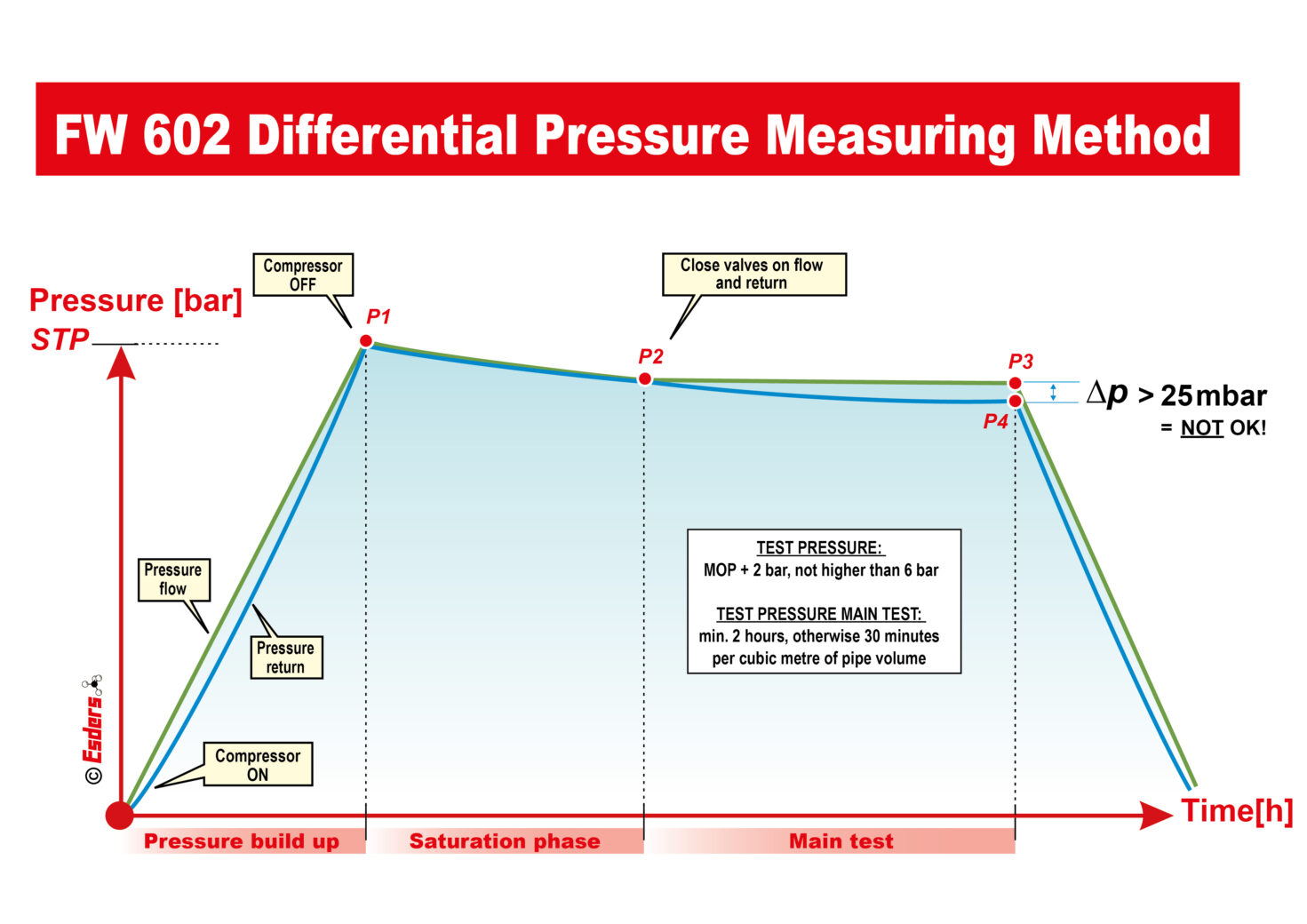

Differential pressure measurement method

The differential pressure measurement method is an overpressure test with air. It is carried out simultaneously on both pipes of the installed service pipelines, i.e. flow and return. The evaluation is carried out via the course of the differential pressure between the two pipes. The method is suitable for all materials and is particularly recommended for PE pipes. The procedure requires identical pipelines.

The test is carried out with air and the materials of the flow and return must be identical. The test pressure is applied to both pipes at the same time, i.e. the pipes must be connected to each other. The hydraulic connection of both pipes remains in place during the adjustment phase.

In the following main test, both pipes are separated from each other and the differential pressure between them is observed and recorded via a pressure measuring device, e.g. our smart memo. The differential pressure is thereby determined by a difference formation of both absolute pressure sensors. The procedure is assessed by the change in differential pressure during the main test.

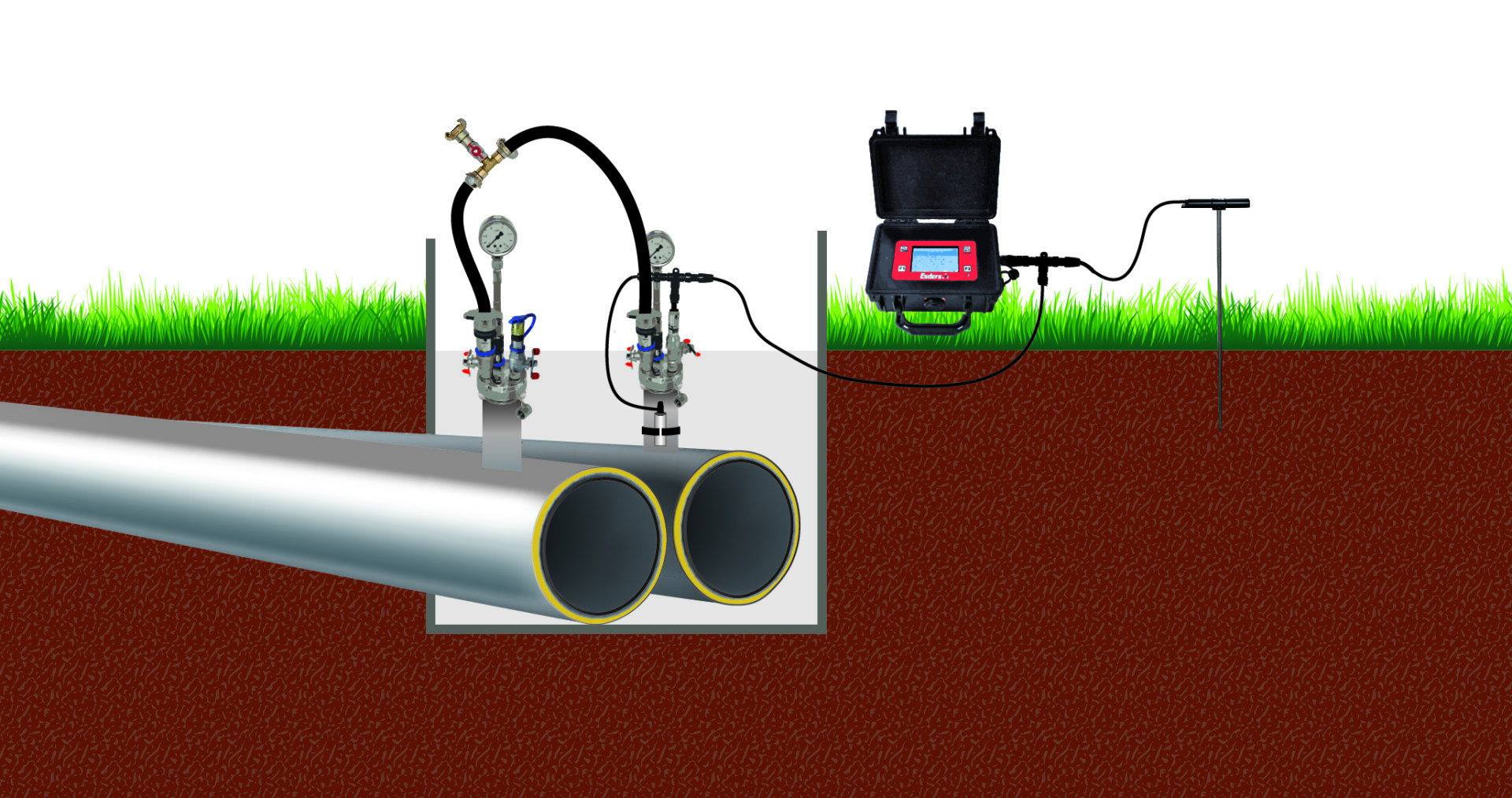

Pressure measurement method

The pressure measurement method is a test with positive air pressure. A single pressure sensor is required for this. The evaluation is made on the basis of the absolute pressure value during the test phase. With the pressure measurement method, an integral test of control sections is carried out, i.e. flow and return can also be tested together with this method, provided the pipes are hydraulically connected to each other. This method is not suitable for PE pipes or in conditions with large temperature fluctuations. If both pipes (flow and return) are to be tested as a composite, they may have different pipe data (diameter, length, etc.).

The test is carried out with air. The test can either be carried out for only one pipe (flow or return) or both pipes (flow and return) can be tested together as a connected pipe. Since in this case the pipes are considered as a compound with a total volume (individual volumes are simply added up), a pressure sensor and a contact sensor are sufficient to test the entire pipe. The hydraulic connection of both pipes (via a suitable hose) remains in place during the entire test.

After the test pressure has been applied to the individual pipe or to the entire pipe network, the adjustment phase (temperature adjustment) follows, the duration of which depends on the total volume.

In the following main test, the absolute pressure in the test pipeline is checked and recorded via the pressure gauge.

The evaluation of the pressure measurement method is carried out via the change in absolute pressure during the main test.

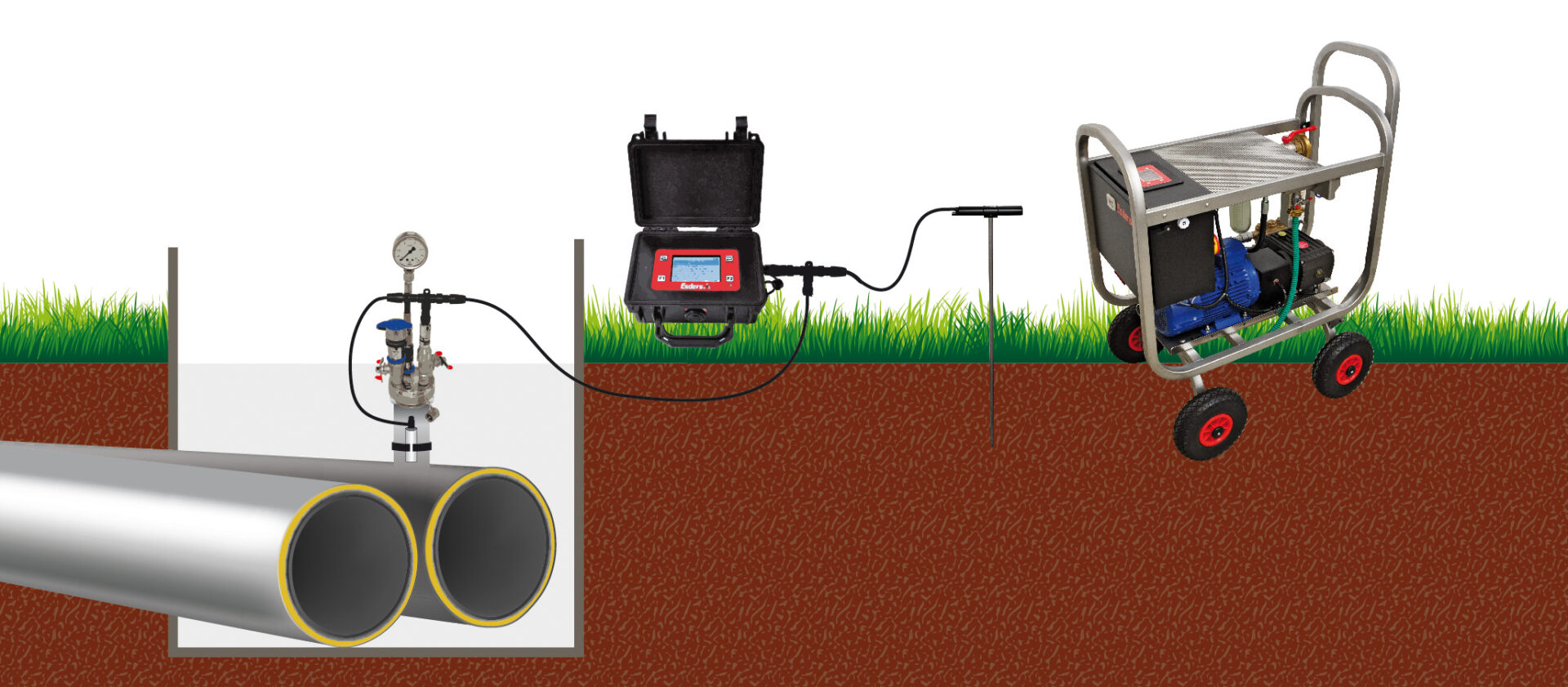

Water pressure test

Some pipes require testing with water pressure. It is used to test the tightness internal pressure resistance of preassembled pipe sections or test sections. The test is performed with a single pressure sensor and can be performed for several adjacent or interconnected sections of a total pipe network.

The test procedure includes two soak periods at the selected test pressure with an intermediate pressure reduction. The pressure drop during the second soak interval is decisive for the evaluation of the test.

Measurement devices and accessories

You can find out which measuring devices and equipment are required for all three test methods in our new category APPLICATION. Here we explain in detail how you can carry out a pressure test in accordance with FW 602 with our equipment and which measuring devices and accessories you need for this (including indication of the corresponding article number). You can then easily purchase them in our new online shop. After registration in Esders Connect, all prices for the respective products will be displayed on the website.

Download all information

Click on the link below now to download all the information and insights you need. Downloading will give you access to:

- detailed insights into the latest testing methods and technologies

- expert analyses showing the importance and impact of these methods

- practical application examples to help you put theory into practice.

Download all the information now and expand your expertise!