Table of Contents

Each pressure test in range W 400-2 includes a pressure drop test which is used to check that no air is present.

Sufficient absence of air within the pipeline to be tested must be ensured, otherwise the results of the pressure test may be falsified. If there is still a small amount of residual air left in the pipeline, a possible leak could be covered by the expanding residual air, i.e. the pressure is kept at a constant level during the main test by the air component.

The warranty and the verification of a complete air release are therefore critical factors in a pressure test.

In the current version of the German Code of Practice DVGW W 400-2, they therefore receive special attention.

Prerequisite for a successful pressure test

The pipeline section to be tested is filled with drinking water and vented. The basic prerequisite for assessing the tightness of a pipeline is sufficient venting. This cannot always be achieved by flushing with water, so pigging should be carried out in these cases.

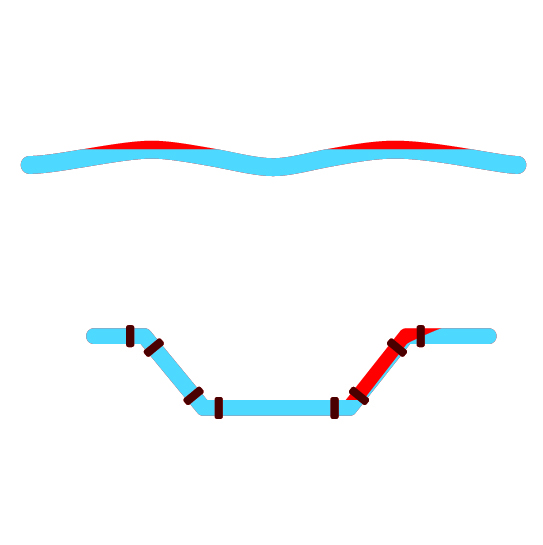

Pipelines that are laid using trenchless methods, for example, have proven to be problematic. This method of laying can lead to the pipeline not only being laid horizontally, but also undulating. Culverts can also be problematic. In the higher sections, air cannot be safely removed by simple flushing. Under difficult conditions, an increase in flushing speed or a longer duration of flushing is not sufficient to remove the residual air. Marked in red in the picture are typical places where residual air accumulates.

What is pigging?

The pigging method is the solution for an air-free pipeline. In this process, a plastic foam body that fits tightly against the wall is pushed through the pipe with the medium water. Due to the space-filling closure up to the pipe wall, any air that may be present is also pushed through the pipeline and can escape at the other end. There, the pig is also removed from the pipe. The pipeline is then completely filled with water and almost free of air. Only very small residual amounts of air can remain, e.g. at pipeline connections.

Examples of pigs

An “air-free” filled pipeline is crucial for a successful pressure test!

You can see in the video how well pigging works.

The pipe simulation is made of PVC so that the filling, flushing to remove the air and the pig can be seen.

In the front area is a section of a roadway like that found in a culvert.

In the rear area is an undulating section of a roadway, as occurs in trenchless pipelaying.

How is pigging carried out in practice?

Pigging is usually carried out in a newly laid pipeline section. For this purpose, there must be components in the relevant section to insert the pig at one end and remove it again at the other end. Suitable parts/components are not always provided for this purpose. For this reason, we recommend considering the installation of T-pieces with flanges already during the planning stage. The pig can be easily inserted through the T-piece. The pig can then be pushed through the pipeline, e.g. with operating pressure from the water network. Via a simple standpipe connected to another T-piece at the end of the section, the flushing water can flow off and the pig can be flushed out.

Take advantage of our latest innovations!

Let us know your contact details and our team of technicians will get in touch with you. Click ‘Get in touch’ now and start your journey to greater efficiency!