Table of Contents

The wastewater network, just like the gas, electricity, and water networks, is part of the so-called critical infrastructure and is therefore subject to special protection. Due to possible attacks on this network as a result of the currently tense political situation, the maintenance and proper operation of this network has become more important than ever. In addition to repairing acute defects, this also includes preventive measures in the form of regular inspections. But how is the network constructed in the first place, what tests and inspections are to be carried out and who is responsible for them?

Structure of the wastewater network

The public wastewater network or sewer network begins shortly after the boundary of private properties. This is usually where there is an inspection manhole, which represents the transfer point from the property owner to the disposal company. The waste disposal company lays the house connection pipe from the main wastewater pipe (or main sewer pipe, hereinafter referred to as sewer) below the street to this manhole. In the event of a malfunction, a pipe can be flushed and inspected from here to determine on whose side there is a malfunction. Sewer manholes are installed in the road or in the sewer approximately every 50 m to 100 m, mostly made of prefabricated concrete rings of size DN 1000. These manholes, which are several metres deep, can be recognised by the well-known round “manhole covers” with ventilation holes. The sewers are laid with a gradient so that the wastewater can flow without pressure to the lowest point of an area via so-called free-fall pipes or gravity pipes. There are two different systems:

- Mixed system: Wastewater and rain water are discharged in a common sewer. During heavy rainfall, there is a problem of overloading in this system.

- Separate system: Wastewater and rainwater are discharged in separate sewers.

Before the wastewater, which is discharged without pressure, reaches the treatment plant for reprocessing, it is routed to pumping stations. These are usually located at the lowest point of a network section and pump the wastewater into pressure pipes to the treatment plant. The wastewater from a separate network section can, under certain circumstances, also be pumped with the help of a pumping station into the sewer system of an adjacent network section, where it can then in turn flow via the gravity lines to the next pumping station. The pipes behind a pumping station are always pressure pipes and must therefore fulfil different requirements than the gravity pipes.

There are different pumping stations:

- Small pumping stations, which are housed in a PE or concrete manhole, several metres deep and usually accommodate one or two pumps. A small pumping station is a property drainage system which, as a so-called pressure drainage system, takes over the disposal of wastewater from buildings and properties in outdoor areas or new development areas below the backwater level.

- Main pumping stations, on a somewhat larger scale, located in special manholes and usually at the lowest point of network sections, operated to overcome large differences in height or piping under ditches and rivers.

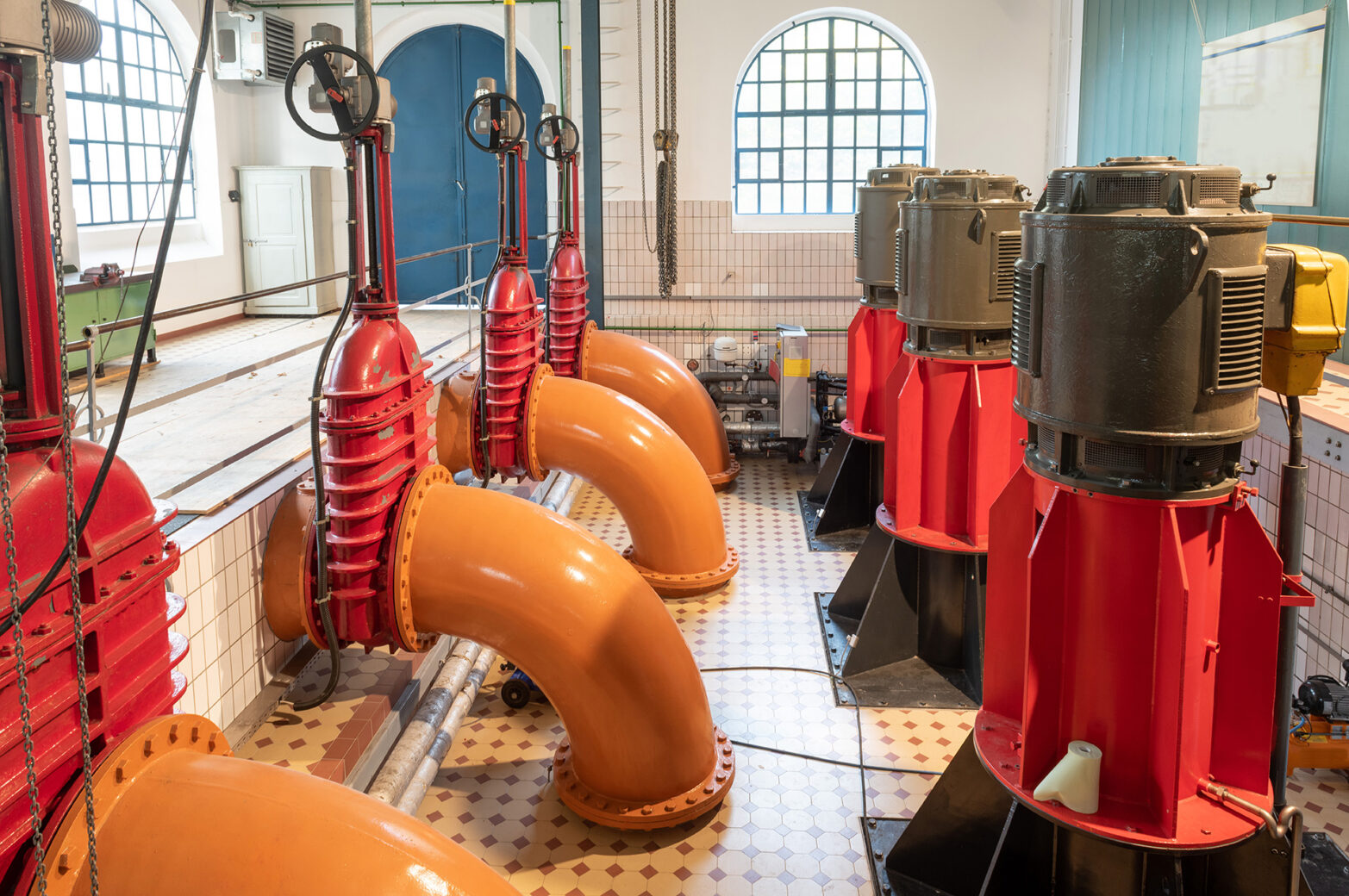

- Large pumping stations housed in their own enclosure and intended for the disposal of wastewater in the municipal, urban or industrial sector.

The pumping stations usually have electrical, measurement, control and often also data transmission technology, e.g., LoRaWAN® radio technology, installed.

Who is responsible for the wastewater network?

In principle, according to the Water Resources Act (in Germany Wasserhaushaltsgesetz – WHG), cities and municipalities or communities as legal entities are obliged to establish and maintain a suitable infrastructure for the discharge of wastewater and its treatment. However, the ownership structures and thus responsibilities for the construction and operation of wastewater networks are very heterogeneous in Germany and range from small wastewater utilities in rural areas to combined drinking water and wastewater associations to large water utilities in urban areas, which also take over both sectors. Like municipal utilities, which are typically responsible for energy supply and occasionally also telecommunications, the municipality, city, or state usually holds a large part or all of the shares in the companies. In some parts of the country, districts, smaller towns, and municipalities also join forces and jointly establish a local or regional water/wastewater association.

Which regulations are relevant?

In Germany, DIN EN 1610 applies to the installation, construction and testing of wastewater pipelines. This is a European standard with the status of a national standard (DIN), which regulates the installation and testing of wastewater pipelines and sewers outside of buildings. Supplementary, national regulations on this area of application can be found, for example, in worksheet DWA-A 139. Both sets of rules also contain specifications for leak tests of pipelines, manholes and inspection openings, which must be carried out once after new construction or repair to ensure proper construction in the sense of an acceptance test.

DIN EN 1610 and the DWA-A 139 worksheet specify requirements for the testing of gravity pipelines. Pressure pipelines that are installed behind pumping stations, for example, must be tested according to the specifications in EN 805. Specifications for the area of building and property drainage, i.e., for pipeline systems on a private property up to the transfer point, are defined in the standards of the DIN 1986 series.

Recurring inspections of drainage systems in operation for the purpose of condition assessment and maintenance are described in the regulations DIN 1986-30 for buildings and land and in DIN EN 752 for the area outside buildings, i.e., also the public sewer system.

When entering (one also says driving into or descending into) manholes, regulations, or rules of the German Social Accident Insurance (DGUV – from Deutsche Gesetzliche Unfallversicherung) apply. The DGUV rules 113-004 and 103-003 should be mentioned here in particular. Among other things, these describe when and how clearance measurements must be taken and what protective measures must be taken before descending into the manhole.

There is also DGUV Principle 313-002 for training as a specialist in clearance measurement and in the use of gas detectors. Before entering a manhole, a risk assessment must be carried out by the contractor, i.e., the responsible operator, and the specified measures must be recorded in a permit or operating instructions. Typical hazards are the risk of falling and dangers due to substances (explosive or toxic gases, lack of oxygen, etc.). As manholes are Ex-zones, special hazard assessments and work instructions must be drawn up for them.

The main pumping stations are to be regarded as technical installations in potentially explosive atmospheres. Here, an explosion protection document must be prepared for each pumping station, which must be inspected at regular intervals by an independent inspector. Associated manholes can also be listed in these documents.

What are the current challenges?

Since the regulations are becoming more and more detailed and strict, and thus the demands on specialized personnel in the wastewater sector are increasing, but at the same time there are fewer and fewer qualified staff available, the industry is facing enormous challenges. In addition, water is a scarce commodity and the contamination of water, e.g., through contamination with medication residues, is increasing. This increases the demands on the treatment of wastewater.

Not least due to the now omnipresent discussion on climate protection, the drastic increase in energy costs and the increased danger of cyberattacks during digitalization, the wastewater sector must also rethink and partially reposition itself.

The tightness of the wastewater network also plays an important role. Additional water ingress from e.g., groundwater in defective wastewater pipes must ultimately be treated in the same way as the actual wastewater and thus causes further costs in the treatment plant. Moreover, the additional water must be pumped through all downstream pumping stations to the treatment plant and thus leads to rising energy costs.

In this context, compliance with prescribed leak tests after the installation of a drainage system according to DIN EN 1610 provides a great savings potential.

A higher degree of automation and further developed possibilities for remote monitoring could also help to carry out the maintenance of the plants in a more targeted manner. Due to the largely very (time-) consuming and thus expensive inspections in combination with a lack of staff, in many places prescribed and possibly also actually required inspections cannot be carried out in time. In the worst case this leads to damage to installations that could have been avoided if the tests or inspections had been carried out in time, accordingly reducing costs.

Subscribe to our newsletter and stay informed

If you would like to be kept up to date with changes to regulations, new products, news on the blog and much more, please fill in the form below.