Table of Contents

In Germany, more than 95% of the population is connected to the wastewater system, which means that Germany has a very large wastewater network. We have also summarized more information on the wastewater network in Germany for you here. Our wastewater system is also part of the important and critical infrastructure alongside drinking water pipelines and pipelines for energy supply (e.g. gas, district heating, etc.).

In addition to the use of suitable and durable construction and materials, the prerequisite for a long-term functioning and watertight sewer network is, above all, the professional construction of the wastewater pipelines and sewers. Thus, there are also specifications for the wastewater network with regard to construction, commissioning and maintenance of the individual components, comparable to the drinking water network.

Tight wastewater pipelines have a great influence on the local water balance in many respects and protect the resource water. With a dense wastewater network, up to a quarter less water would have to be treated in the wastewater treatment plants, the purification capacity of these plants would increase, but with less energy input. In addition, leaky pipes act like drainage pipes and can lower the groundwater level or, in the worst case, even contaminate the groundwater.

In the following, we describe the most important regulations for the wastewater network with regard to the inspection of wastewater pipelines and sewers and show the differences in the individual regulations and procedures for the German wastewater network.

Expand your understanding of DIN EN 1610 and always stay up to date. Your expert knowledge is just a click away – download now!

What is DIN EN 1610?

The EN 1610 standard describes the European standard for the installation and testing of wastewater pipelines, sewers and manholes in drainage systems outside buildings. It is a detailed standard for the superordinate standard EN752, which deals with drainage systems outside buildings on a much more general level. The standard applies to the public sewerage network.

In EN 1610, test procedures are provided as an acceptance test for newly laid pipelines, sewers or manholes. An acceptance test must also be carried out after the renewal of pipelines. The specifications of the following test procedures apply exclusively to unpressurised pipeline sections under gravity conditions (gravity lines, gravity pipes). Pipelines that are operated under pressure, e.g. pressure pipelines behind a pumping station, must be tested according to the requirements from the EN 805 standard.

The EN 1610 standard provides two procedures for leak testing of gravity pipelines: method “A” with the test medium air and method “W” with the test medium water.

We explain the individual test procedures below:

The DIN EN 1610 Procedure Air "A“

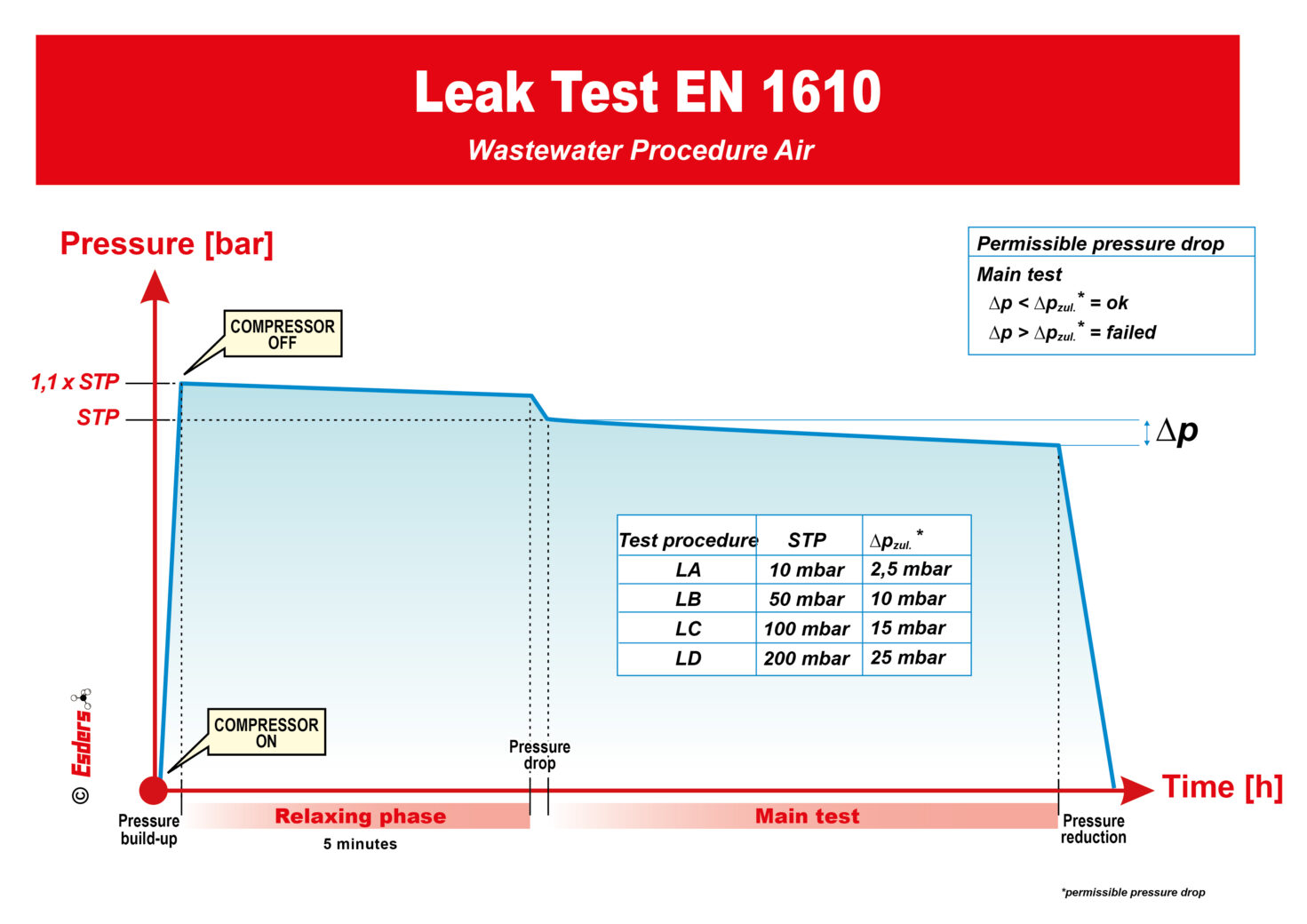

This procedure is carried out with overpressure, using air as the test medium. It can be carried out at different test pressure specifications, which results in a further subdivision of the procedures:

LA 10 mbar test pressure

LB 50 mbar test pressure

LC 100 mbar test pressure

LD 200 mbar test pressure

The sequence of each procedure consists of a pressure build-up phase (to 1.1xSTP), a settling phase (duration 5 minutes), a pressure reduction to STP and a main test phase.

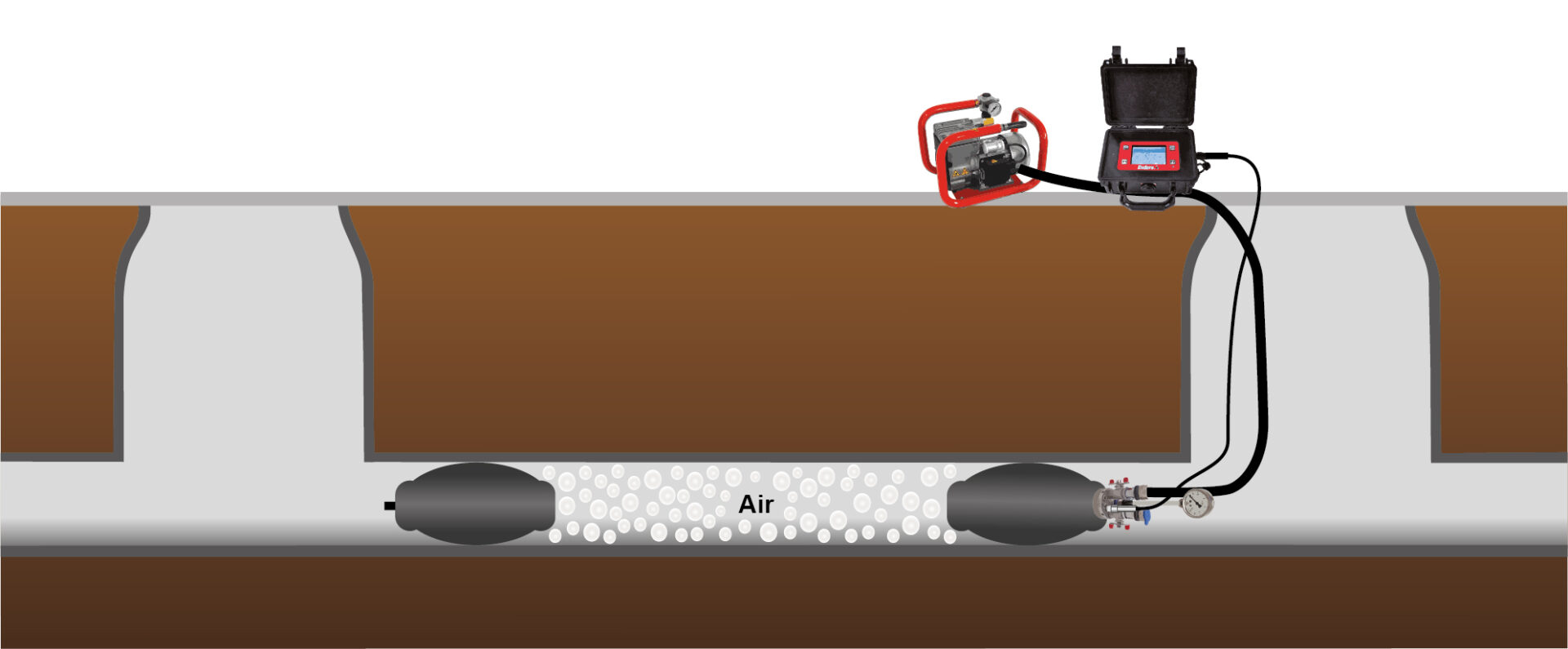

Values for the duration and permissible pressure drop of the main test are specified for each test pressure specification. To perform the test, sealing pads (shut-off bladders) are usually used to isolate the section/manhole to be tested. Pressure measurement technology with sufficient accuracy (error limit maximum 10 % of the permissible pressure drop) is required to perform the test.

The air method is probably the most common method, as it can be carried out on most pipelines and sewers with manageable effort (in terms of measurement technology and working time).

According to DIN EN 1610, however, manholes and inspection openings should be tested using the water “W” method, which is described below.

The DIN EN 1610 procedure water "W"

This procedure is carried out with the test medium water and is usually used for manholes and inspection openings. The manhole to be tested is insulated with appropriate shut-off technology (sealing pad) and then filled up to the upper edge of the cone or to the lower edge of the cover plate. The water column in the manhole creates a test pressure, which would theoretically have to be measured and maintained during the test.

After the manhole has been filled, a settling phase (optional) can take place, then the 30-minute main test starts, which is a water loss measurement, so to say. In contrast to a pressure loss measurement, it is not the pressure drop in the test object that is the decisive evaluation variable, but the amount of water supplied that was necessary to restore the “initial” state at the start of the test. The “initial state” can either be achieved by means of a pressure measurement (as described in EN 1610) or analogously by means of a level measurement of the water column in the manhole.

During the main test, a possible level drop is measured with the help of a level probe, whereupon the original level can be restored by adding a certain amount of water. The permissible amount of water during the 30-minute main test at a manhole is e.g. 0.4 litres/square metre of manhole surface. In the case of a DN1000 manhole with a depth of 4 meters, this is therefore approx. 5 litres of permissible water quantity.

The worksheet DWA-A 139

For Germany, the German Association for Water, Wastewater and Waste (DWA) develops supplementary, national regulations to EN 1610 in the form of leaflets and worksheets. Worksheet DWA-A 139 thus has a comparable scope to EN 1610 and contains additional requirements for wastewater pipelines, sewers and manholes newly built in Germany.

In the following, we will deal exclusively with the differences in the requirements for leak testing between DIN EN 1610 and DWA-A 139.

The differences in DWA-A 139 Procedure Air "A"

Worksheet DWA-A 139 contains supplementary regulations to DIN EN 1610, which is why the procedure basically follows identical specifications. Differences exist in some details, e.g. according to DWA-A 139, only the use of the LC and LD procedures is permitted for metrological reasons. In addition, a suitable test procedure must be selected depending on the groundwater level. For groundwater levels above the pipeline bottom, only the LC procedure is permitted; for groundwater levels above 1 meter above the pipeline bottom, only the water “W” procedure is to be used. The groundwater level must be documented. If necessary, the test pressure must also be increased in accordance with the groundwater level.

According to DWA-A 139, leak tests of manholes are to be carried out exclusively according to the water “W” procedure. Overall, the water “W” procedure is considered more meaningful in the DWA-A 139 worksheet and is referred to as the authoritative test.

The differences in DWA-A 139 Procedure Water "W"

The test according to the water procedure “W” is largely carried out according to the specifications from EN 1610. It serves as the authoritative test and can be carried out as a repeat test if the test according to the air procedure “A” fails. The permissible water addition values from EN 1610 are used as the evaluation criterion for the main test. Level probes with a measuring accuracy of 1 mm should be used to restore or maintain the “start condition” of the test object.

The DWA-M 149 Code of practice for wastewater pipelines in existing contexts

The DWA has issued the DWA-M 149 series of worksheets for the “Recording and assessment of the condition of drainage systems outside buildings”. Part 6 (DWA-M 149-6) describes how the condition of drainage systems in operation can be assessed with the help of a pressure test.

Wastewater pipelines and sewers in buildings can again be tested using the “A” procedure or the “W” water procedure, whereby the limit values and specifications for the tests are much more moderate, i.e. newly laid pipelines are subject to higher requirements for the leak test than pipelines already in operation.

Thus, test pressures, settling times, test times and values for the permissible pressure drop (method “A”) or for the permissible water addition (method “W”) are adapted accordingly.

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)