Table of Contents

Examples of flammable gases: methane, propane and butane

In addition to methane, propane (C3H8) and butane (C4H10), which frequently occur in liquid form, are also flammable gases. Under normal conditions (atmospheric pressure, room temperature) they are gaseous, but can be liquefied at room temperature with relatively low pressure. They have a higher relative density than air and therefore remain on the ground in a gaseous state. All three gases, along with ethane (C2H6) – another component of natural gas – belong to the hydrocarbons, as they consist of one or more carbon atoms, each with associated hydrogen atoms.

Methane

Methane occurs in many places on Earth and is constantly being formed, e.g. during geological processes. The methane concentration in the Earth’s atmosphere is just under 2 ppm. Methane is also formed when organic substances rot in the absence of air or during anaerobic fermentation as a mixture with carbon dioxide, e.g. in swamps or during decomposition processes in nature. Terms such as sump gas, digester gas, sewer gas, sewage gas or landfill gas are also frequently used for this mixture, as it can also be produced at landfills or in wastewater or sewer manholes. Unlike natural gas, however, these mixtures do not contain ethane or higher hydrocarbons such as propane and butane. Biogas produced in biogas plants contains about 60 vol.% methane and 35 vol.% carbon dioxide.

Hydrogen: energy carrier of the future

Hydrogen (H2) is also a flammable gas, but hardly ever occurs in pure and gaseous form in the wild. Most of the hydrogen found on earth is bound in water and must therefore be produced artificially, e.g. by electrolysis of water. Since the combustion of hydrogen produces pure water vapour (H2O) and no CO2 emissions, it is seen as the energy carrier of the future in the fight against climate change.

In the meantime, hydrogen is already being added to natural gas in quantities of up to 10 vol. %. Higher blends of 20 vol.% or 30 vol.% H2 are being tested. In addition, pure hydrogen networks (i.e. 100 vol.% H2), often as small isolated solutions in the vicinity of generation plants or large transport pipelines, are operated for energy supply and hydrogen filling stations for the transport sector.

Properties of flammable gases: explosion limits and ignition temperature

For flammable gases, the minimum ignition temperature and energy as well as the ignition range are important properties. The ignition range or explosion limits indicate the range within which ignition or explosion can occur in a mixture with air or oxygen.

In addition, the minimum ignition temperature and energy are required. This is why the so-called explosion triangle, consisting of fuel, oxygen and ignition source, is often cited for flammable gases.

Only when these three factors occur together can an explosion take place. In other words, no ignition or explosion can take place in the absence of one of the three factors.

The explosion limits are referred to as LEL (lower explosive limit) and UEL (upper explosive limit). The LEL of methane is 4.4 vol.%, the UEL is 17 vol.%.

For hydrogen, the ignition range is much larger, as the LEL is 4 vol.%, but the UEL is 77 vol.%. In addition, the ignition energy of hydrogen is more than ten times lower than that of methane. This is why gaseous hydrogen is so dangerous and classified in the higher explosion group IIC compared to IIA for methane.

Other flammable gases are acetone, benzene, ethanol, ethylene, ethylene oxide, hexane, i-propanol, n-nonane, methyl methacrylate, and many more, which are mainly found in industrial applications.

Safety measures when working with flammable gases

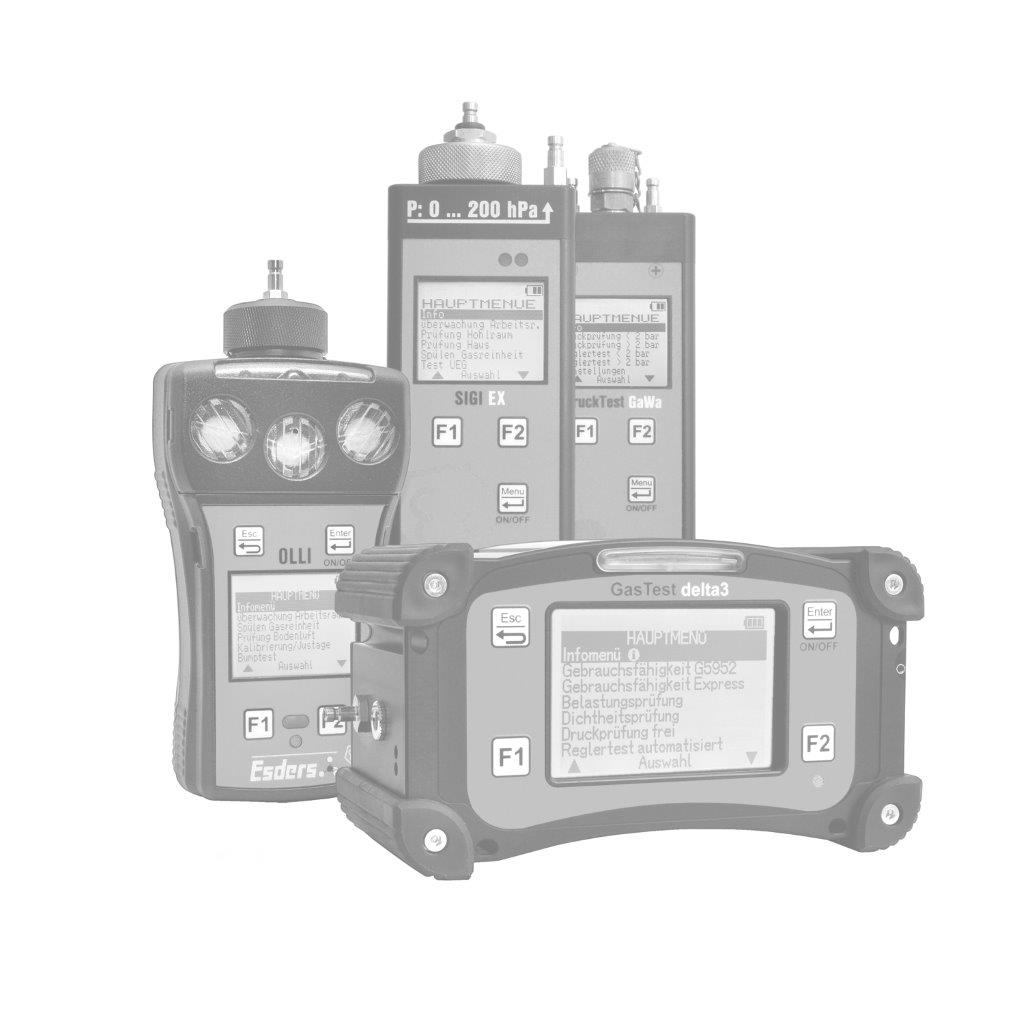

A high degree of caution is required when handling flammable gases. For this reason, stationary or mobile or portable gas detectors are used for personal protection, such as our device OLLI.

DGUV Rule 113-004 requires trained personnel with expertise in measuring devices, measuring methods and the hazardous substances to be measured for clearance measurements in containers, silos and confined spaces. To implement appropriate safety measures in practice and to protect your employees, we offer a seminar on technical knowledge for clearance measurement.

.jpg?width=100)