Table of Contents

Water is a scarce and therefore precious resource that must be protected with all available methods. This means that leaks in drinking water distribution systems (DWDS) must be found quickly in order to minimise water losses.

Pressure test before commissioning water pipes

In order to determine the tightness of a new pipeline before it is put into operation, there is the DVGW worksheet W 400-2 in Germany, which was published in a new version in August 2022. It sets out technical standards and clear specifications for testing pipelines, which already ensure a high level of operational safety to protect water as a resource.

Automated leak detection – correlation

For pipelines in operation, automated and permanent leak detection can take place using the principle of correlation. This involves measuring the transit time difference of sound waves in the pipeline with the help of ground microphones. These sound waves are generated by escaping water due to leaks and “move” along the pipeline. The application of this principle is particularly useful with metal pipes, as these transmit sound well.

In newer pipes made of plastic, the sound can spread more poorly. In addition, this method is now reaching its limits in practice, as leaks are more difficult to locate due to increased disturbing background noise. In addition, the use of ground microphones and associated noise loggers (correlators) requires high initial investments and ongoing operating costs, which, depending on the type of network or pipelines and their quality, only pay for themselves relatively late. Therefore, it is not always possible to find leaks in an economical way with this method.

Leak detection on water pipelines with tracer gas

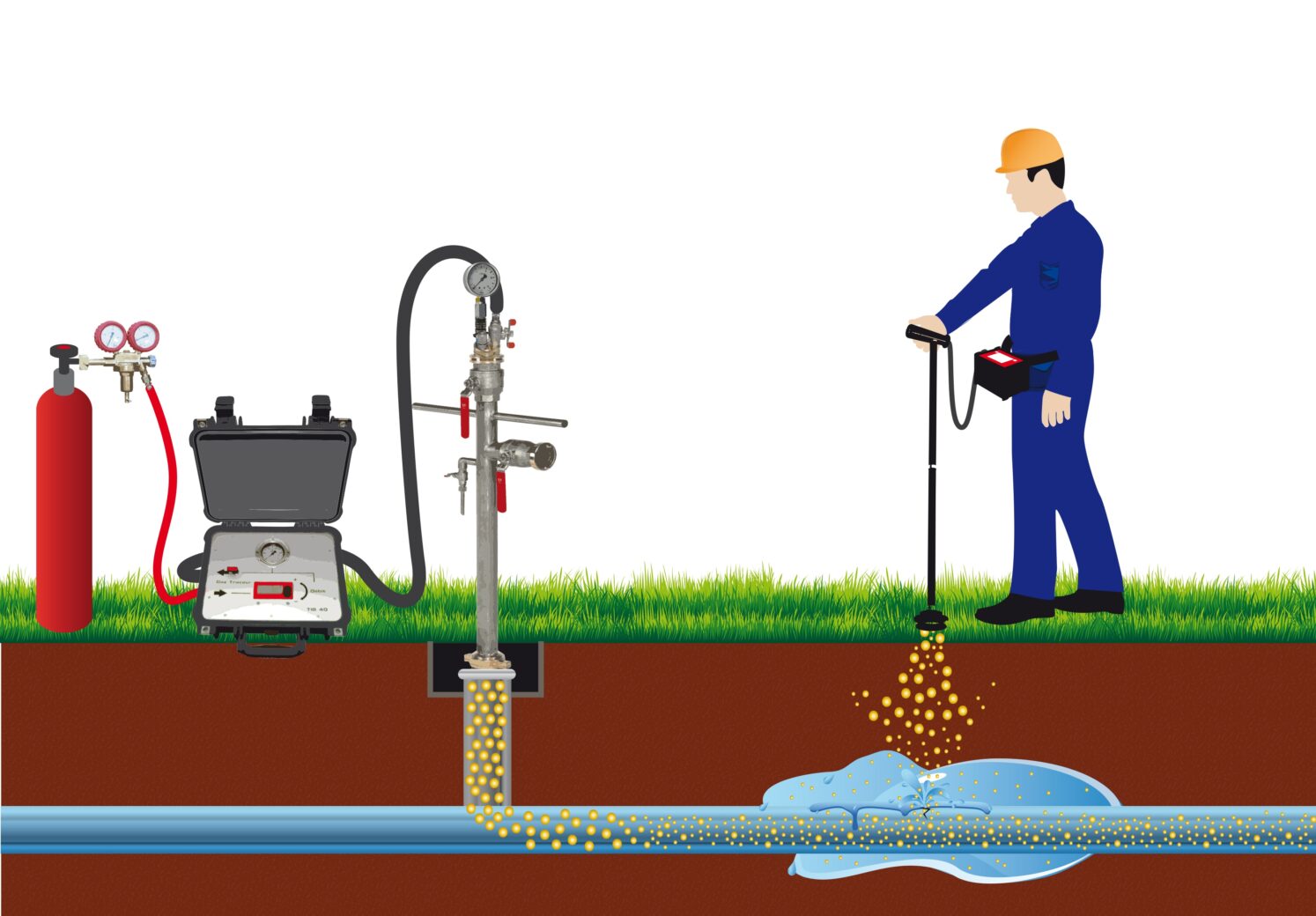

With the tracer gas method, there is another, relatively inexpensive possibility for leak detection. This method is also used to detect leaks in air conditioning systems in vehicles, but can also be used on water pipes. Here, “forming gas” or “tracer gas” is injected into an operating water pipe.

What is tracer gas?

The gas usually consists of 5 vol.% hydrogen and 95 vol.% nitrogen. Occasionally there is also a ratio of 10/90 or even 20/80, the latter usually being used as a shielding gas in welding. The advantage of a 5% hydrogen content is the fact that this mixture is non-flammable and therefore very safe to use. In the past, helium was also used as a carrier gas instead of nitrogen. However, since helium has become relatively expensive in the meantime, the combination of hydrogen and nitrogen is predominantly used.

How does the tracer gas method work?

The principle of this method is the same as for above-ground leak detection on buried gas pipelines. Due to its very small molecular size (it is the smallest gas molecule), the hydrogen injected with the tracer gas also reaches the outside through small leaks in the pipeline. Due to its low density, hydrogen is lighter than air and therefore rises to the top. Above the pipe, the gas is detected (pre-location) with a suitable probe (e.g. carpet or bell probe) and a gas detector calibrated for hydrogen (e.g. HUNTER Tracer Gas).

In the case of very small leaks or difficult ground conditions and the associated difficulties in detection, a mobile vacuum pump can also be used to extract the gas above the ground with a special bell probe and feed it to the measuring device. With a borehole probe, the gas concentration in the soil can be measured after an above-ground detection of hydrogen in order to precisely locate the leakage point (localisation).

How much tracer gas is needed and where is it injected?

The amount of tracer gas added depends on the prevailing water temperature and water pressure and is between two and over ten percent of the water flow. This amount can be easily dissolved in the water and no problems arise during ongoing operation in the distribution system. The size of the leak also plays a role. The larger the leak, the more gas has to be injected. Even if the leak is in the most unfavourable place, e.g. the bottom of the pipe, the water-gas mixture will escape there. However, the altitude or the course of the pipeline must be taken into account if the leak is at a lower point than the planned injection point. In this case, another point should be chosen for the injection that is lower.

Suitable injection points are generally:

- Hydrants

- Dismantled water meters

How is tracer gas injected?

The gas is usually fed into the system via high-pressure cylinders with suitable pressure reducers. To ensure the desired injection quantity, the use of a flow meter is recommended, e.g. the injection box TIB 40. In the case of leaks in house connection pipes, the injection can be carried out via the water meter connection after the meter has been dismantled. The tracer gas then “flows” against the regular flow direction of the water up to the leakage, since no regular water withdrawal takes place and the water in the house connection pipe does not flow.

After the injection, one should wait a certain time before starting the pre-location by means of a gas detector and probe, as the gas needs some time to reach the surface. This is mainly influenced by the amount of tracer gas injected and the size of the leak as well as the soil properties and permeability.

What are the advantages of tracer gas?

The tracer gas method avoids time-consuming and expensive excavations that would otherwise be necessary if acoustic methods such as correlation cannot be used or cannot be used well (e.g. with plastic pipes).

Another advantage of this procedure is its use on hidden water pipes in the installation area (e.g. lying behind plaster). The pipes cannot be checked for leaks using acoustic methods. The same gas detector that is already used for above-ground leak detection outside can also be used here. For this purpose, only the probe is exchanged and a gooseneck is mounted on the device via a quick coupling.

Due to its small molecular size, the hydrogen contained in the tracer gas also penetrates brick walls and plaster. This often makes it possible to detect leaks that would otherwise be difficult to find.

If you would like to find out more about tracer gas or other specialist topics, please subscribe to our newsletter and make sure you don’t miss anything. We regularly prepare interesting technical topics and always keep you up to date.