Table of Contents

Until now, the focus of pressure tests for gas pipelines according to DVGW was on natural gas. However, due to the increasing use of hydrogen (H2) as an energy source, the requirements are changing. With the introduction of the supplementary sheet G 469-B1, the DVGW has now responded to the growing use of hydrogen.

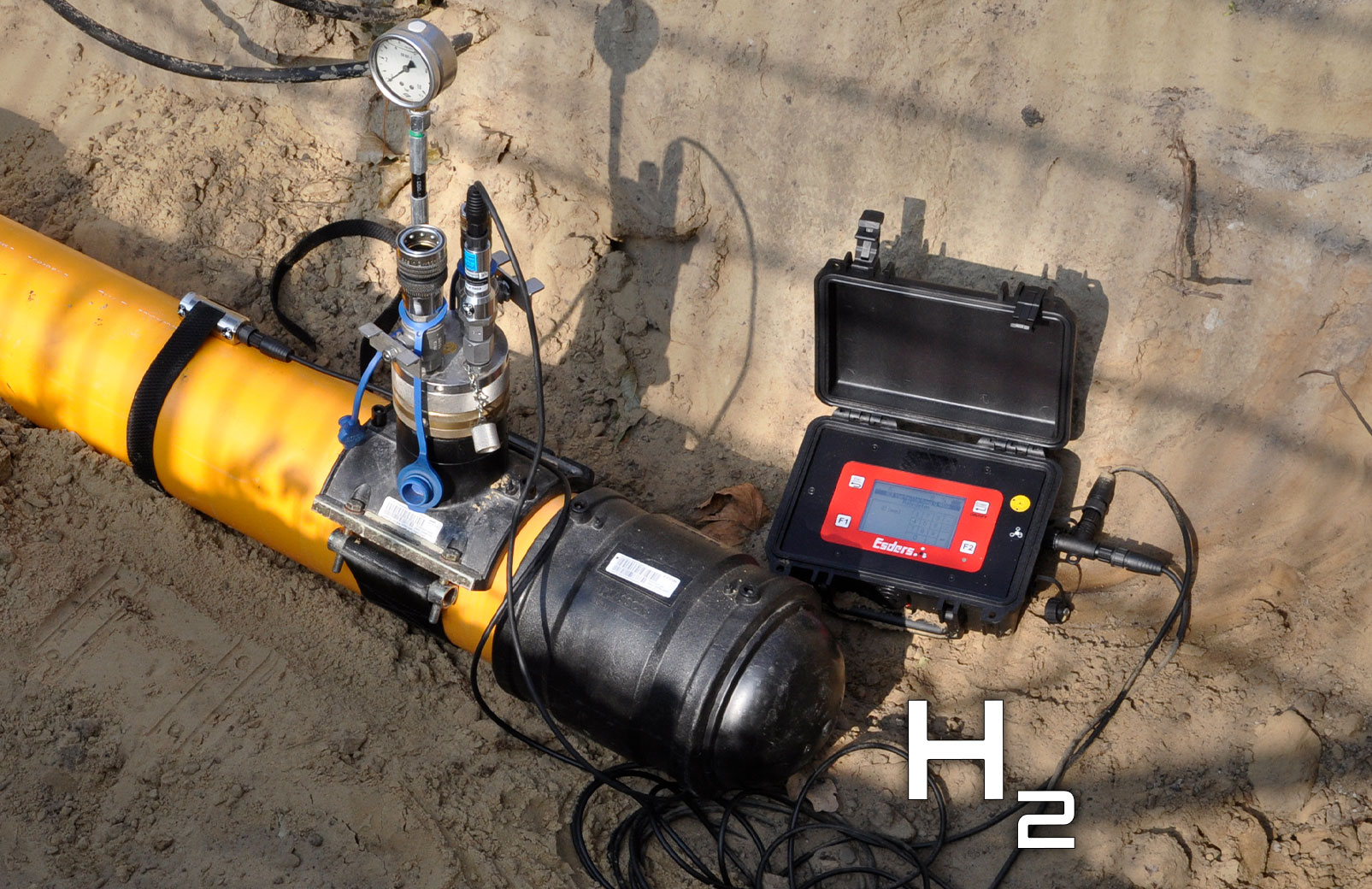

In this article, we will answer the most important questions, explain what new adjustments have to be made and talk about our device for pressure testing of hydrogen lines – smart memo.

What is the significance of DVGW worksheet G 469?

Pressure tests on gas pipes are used in Germany – and in many other countries – as a key method for checking the strength and tightness of the entire pipeline system. Before a new section of a gas supply network can be put into operation, a proper pressure test must be carried out. For this purpose, there are clearly defined instructions, specifications and test procedures that have been established for many years and contribute to the safety of the gas supply network. The DVGW has published the worksheet DVGW G 469 – Pressure test procedure for gas transport/gas distribution for this purpose, which is regularly updated to reflect the latest state of the art. The last update was made in July 2019.

Why use hydrogen? What rules come with using H2?

Since natural gas and methane have been considered primary and inexpensive energy sources in recent decades, the original scope of the G 469 worksheet covers only the proper operation of the gas supply network with natural gas. In the context of the energy crisis of recent years and the resulting energy transition, alternative energy sources such as hydrogen are gaining in importance.

There are already many initiatives and projects underway to prepare and convert existing parts of the natural gas supply network for the admixture of hydrogen. In addition, research projects are being carried out to investigate the holistic conversion of existing gas infrastructure to 100% hydrogen.

Due to the different physical and chemical properties of hydrogen compared to methane, uncertainties arise, among other things, in the area of material compatibility and also in the area of the tightness of pipes. For example, hydrogen molecules are significantly smaller than methane molecules. The smallest leaks in pipes, which have not played a significant role in the use of methane so far, could become very relevant in the use of hydrogen. In order to assess whether current pressure testing methods are still sufficient for natural gas and hydrogen mixtures in the field of gas supply, the DVGW has carried out specific research projects, including the ECLHYPSE project. The research results have led to stricter requirements for pressure tests on gas pipes and have been published in the form of the supplementary sheet B1 for the G 469 worksheet.

What changes does the G 469 B1 supplement introduce to the test procedures?

Worksheet G 469 contains various types of test procedure, which are selected depending on the application. The most common procedures are the visual inspection (visual pressure test) with operating gas A 4 (e.g. for network connection pipelines), the pressure measurement method with air B 3 (e.g. for supply pipelines) and the precision pressure measurement method with air C 3 (e.g. for transport pipelines).

The A4 visual inspection method, which was previously used with natural gas, can now also be used for hydrogen. This means that pipelines that are operated primarily or entirely with hydrogen can also be tested for leaks using the visual inspection method.

In order to ensure a sufficient seal for hydrogen as well, either the test duration of the main test must be doubled or the permissible pressure drop in the main test must be halved from 50 mbar to 25 mbar.

Old formula: t=0,5 h/m^3 × V_geo

New formula: t=1 h/m^3 × V_geo

The minimum test duration is also increased from half an hour to one hour. It is up to the user to decide which of these two parameters is changed.

The already applicable requirement for the measurement technology must be observed, since the measurement uncertainty of the pressure measuring device used may not exceed 1/3 of the permissible pressure drop. So if the permissible pressure drop of the main test is reduced to 25 mbar, the measurement uncertainty of the pressure sensor used should be better than 9 mbar.

Summary:

- Adjustment option 1 – test duration B3: Doubled (new formula: t=1 h/m³×V_geo, previously: t=0.5 h/m³×V_geo).

- Adjustment option 2 – pressure drop B3: Halved from 50 mbar to 25 mbar (optional adjustment by user).*

- Minimum test duration: Increased from 30 minutes to 1 hour.

- Measurement uncertainty: Max. 1/3 of the pressure drop (at 25 mbar → measurement uncertainty < 9 mbar).

* At least one of the two adjustment options must be implemented.

Do you need more information about our smart memo for pressure testing?

Our experts will be happy to provide you with a personal consultation and give you more information about our smart memo measuring device.

Simply use our form to send us a contact request.

The precision pressure measurement method C 3 without measurement of the ground temperature can still be used for pipelines intended for use with hydrogen in accordance with G 469. Supplement B1 merely stipulates a maximum pipeline volume of 50 m3.

For procedure C3 with measurement of the ground temperature, changes are prescribed for hydrogen pipelines, similar to procedure B3, in the duration of the main test or in the permissible pressure drop in the main test.

If the duration of the main test is to be adjusted, it must be doubled.

Old formula: t=0,5 h/m^3 × V_geo

New formula: t=1 h/m^3 × V_geo

The minimum test duration is now four hours.

If the permissible pressure drop in the main test is to be reduced, this must be done according to the following formula:

∆p_zul=± p_abs × 0.7 × 10^(-3)

Compared to the requirements of Code of Practice G 469, this is again half of the previous permissible pressure drop.

Summary:

- C3 without ground temperature measurement: Applicable according to G 469; max. pipe volume 50 m³.

- C3 with ground temperature measurement:

- changes to test time/pressure drop analogous to B 3.

- Minimum test duration: 4 hours.

- Pressure drop: halved (new formula: ∆p_zul=±p_abs×0.7×10⁻³).

- Test time: doubled (new formula: t=1 h/m³×V_geo).

What do these changes mean for smart memo?

For our customers, the smart memo is an indispensable device for performing pressure tests. Menu-driven test sequences guide users through the individual phases of (sometimes complex) test procedures, ensuring a smooth and compliant process. All test sequences in the device are programmed according to the current version of the relevant set of regulations.

Occasional updates to regulations may necessitate changes to existing test procedures. For example, extensive changes were made to the W 400-2 worksheet, which then resulted in significant changes to the test procedures in the smart memo.

As soon as updates to the rules and standards are published, we identify the changes that are relevant for the test procedures and offer them as a software update for an existing test procedure. These software updates are free of charge for our customers.

We also offer a software update for the G 469 B 3 test procedure (option DVGW G 469 B3) that takes into account the changes in the supplement. After the update has been successfully installed on your device, you will be asked when starting the test whether the pipelines are intended for operation with natural gas or hydrogen. Depending on your selection, the test procedure for the ‘old’ requirements or those of the ‘new’ supplement will follow.

You can install the update on your smart memo easily and free of charge using the Esders Connect App.

Don’t miss any news about our products and the topic of hydrogen

.jpg?width=100)