Pipes used for sewage disposal must undergo an acceptance test before being put into operation. This is to verify that the construction work has been carried out properly and that the pipe system is leak-proof. There are various methods for this purpose, which can be selected depending on the structure of the pipe system. This article is about leak testing using the level measurement method.

Automatic test reports

The acceptance test must be carried out in accordance with the procedure specified by the network owner (client) or the planner. The applicable rules in this area are provided by DIN EN 1610: Installation and Testing of Wastewater Pipes and Channels. This standard stipulates that a leak test of newly laid pipelines, manholes and channels in the wastewater sector must be carried out either with air (‘A’ procedure) or with water (‘W’ procedure).

We have already summarised further requirements from the standards and details on the sewage network in an earlier blog article: DIN EN 1610 – Leak test of wastewater pipes.

In the following, we would like to focus on the leak test using the ‘W’ procedure, which we will explain using the example of our measurement technology based on the smart memo.

View your results digitally

The smart memo is a universal pressure test device for carrying out pressure tests or leak tests. By individually configuring different software options, it offers the possibility of carrying out tests in accordance with a specific set of rules or standard. The user is guided through the individual phases of the test by menu-driven processes. All details and requirements of the respective standard are programmed into the smart memo and are taken into account during the test. Finally, the user receives a complete test report that complies with the relevant regulations, including an evaluation of the test. The test report is directly available in digital form and can be accessed at any time and from anywhere via the Esders Connect online portal.

The EN 1610 Wastewater Option provides the appropriate test procedures for leak testing wastewater pipes. This option includes the following two tests: the wastewater air procedure (procedure ‘A’ according to the standard) and the wastewater water procedure (procedure ‘W’ according to the standard).

Leak test with water pressure as level measurement method

The ‘wastewater water procedure’ is provided in the smart memo for carrying out a leak test using the level measurement method in accordance with DIN EN 1610 or DWA-A 139. In this procedure, there are no regulatory differences between the two regulations, so that only the designation of the test changes during execution. However, it should be noted that according to DWA-A 139, manholes may only be tested with water; according to DIN EN 1610, a manhole test with air would theoretically also be permitted.

Different requirements for leak tests

The ‘wastewater procedure – water’ can be used for a single pipe section and for one or more manholes/inspection openings with one or more connected pipes. A maximum of two manholes/inspection openings and three pipe sections can be selected using the device. At least one manhole or inspection opening is required to perform the leak test using the level measurement method. Testing a single pipe using the ‘wastewater procedure – water’ requires different equipment and will be covered in another article at a later date.

Carrying out the test

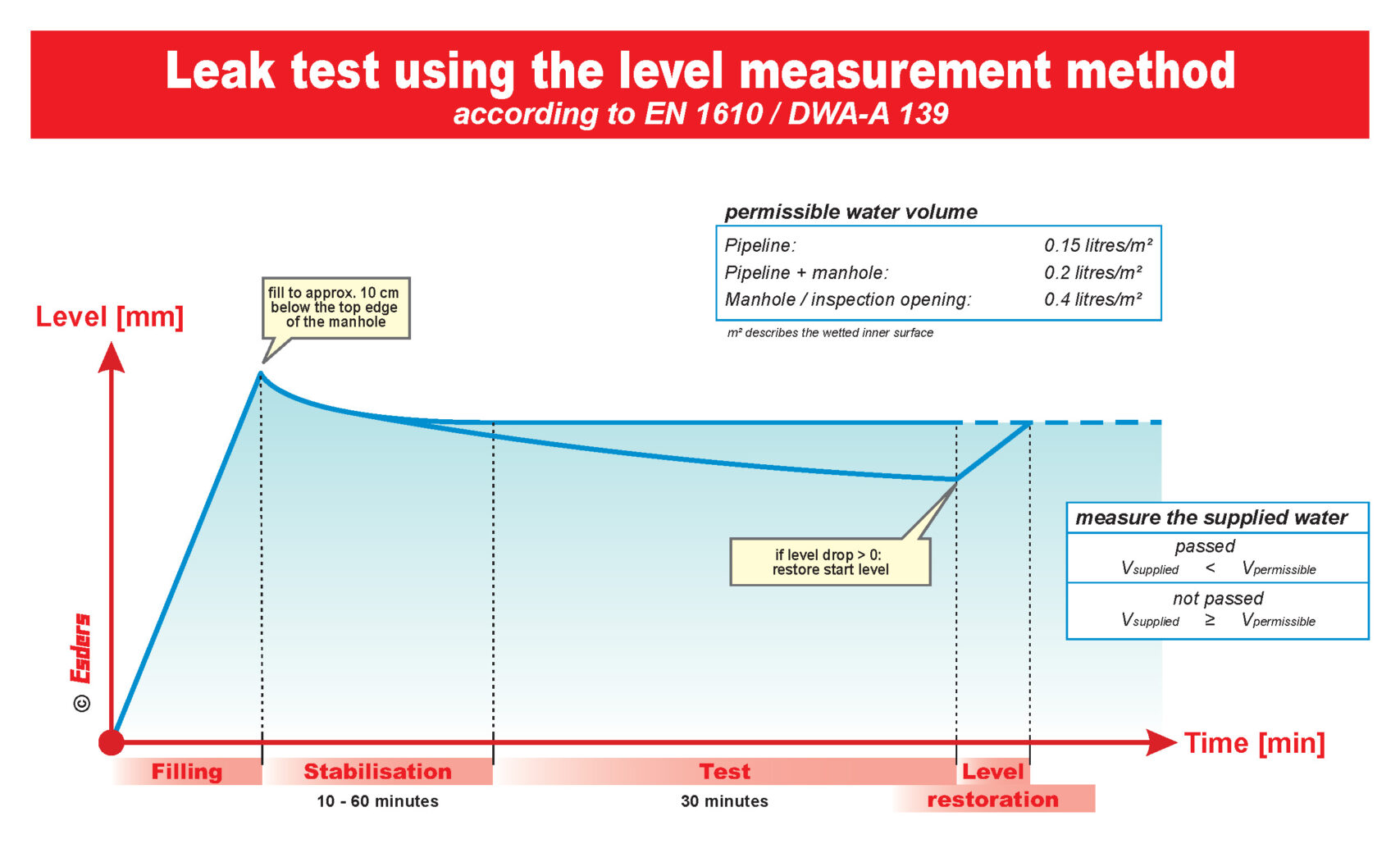

First, the test space for the leak test is sealed off using suitable sealing bags and at least one test sealing bag and then completely filled with water using the level measurement method. The water level in the manhole (or in the inspection opening) is then checked using a level probe. After a necessary stabilisation phase – e.g. while the temperatures of the water, test area and measurement technology adjust – a 30-minute test phase follows. This is shown in the following graphic:

Since this procedure is a type of water loss measurement, the water level should be maintained during the test phase and restored at the end of the test. The supplied water volume required for restoration must be measured and is used to evaluate the test. If the supplied water volume is greater than the water volume permitted by the standard, the test is considered failed. The limit values for the water volume depend on the type of test space and the wetted internal surface. All the data required to calculate the limit values is already available in the smart memo, so that the evaluation of the supplied water quantity is carried out automatically at the end of the test.

How does the water level maintenance or restoration work?

To evaluate the test, the level must be maintained at the beginning of the test phase or restored at the end of the test. This can be done ‘manually’ with the smart memo. The user simply pours water into the manhole using a measuring cup. The refilling can be done step by step during the test phase or once at the end of the test phase (‘phase level restoration’). The amount of water added should always be noted, as the water volume must be entered in the smart memo at the end of the test. The device displays a corresponding prompt for this.

Automatic refilling with smart level control

To simplify this test, we have automated the level maintenance and water volume measurement process and offer the optional module smart level control for this purpose. As soon as the water level falls below a certain limit during the test phase, the smart level control automatically refills an appropriate amount of water and measures the added water volume. Using smart level control means that once the measurement technology has been set up and the measurement started, the test runs fully automatically. At the end, a test report that complies with regulations is generated, including an evaluation and reliably determined measured values.

Send results via wireless data transfer

To carry out this test, a smart memo with the activated option Wastewater EN 1610 is required. The smart memo guides you through the test in an automated process, displays measurement data and progressions and saves and documents all relevant test data. The option LTE-GPS can be used for digital transmission of the test results to the portal Esders Connect. This allows data to be sent directly from the device. Suitable external sensors are required for the test to record measurement data.

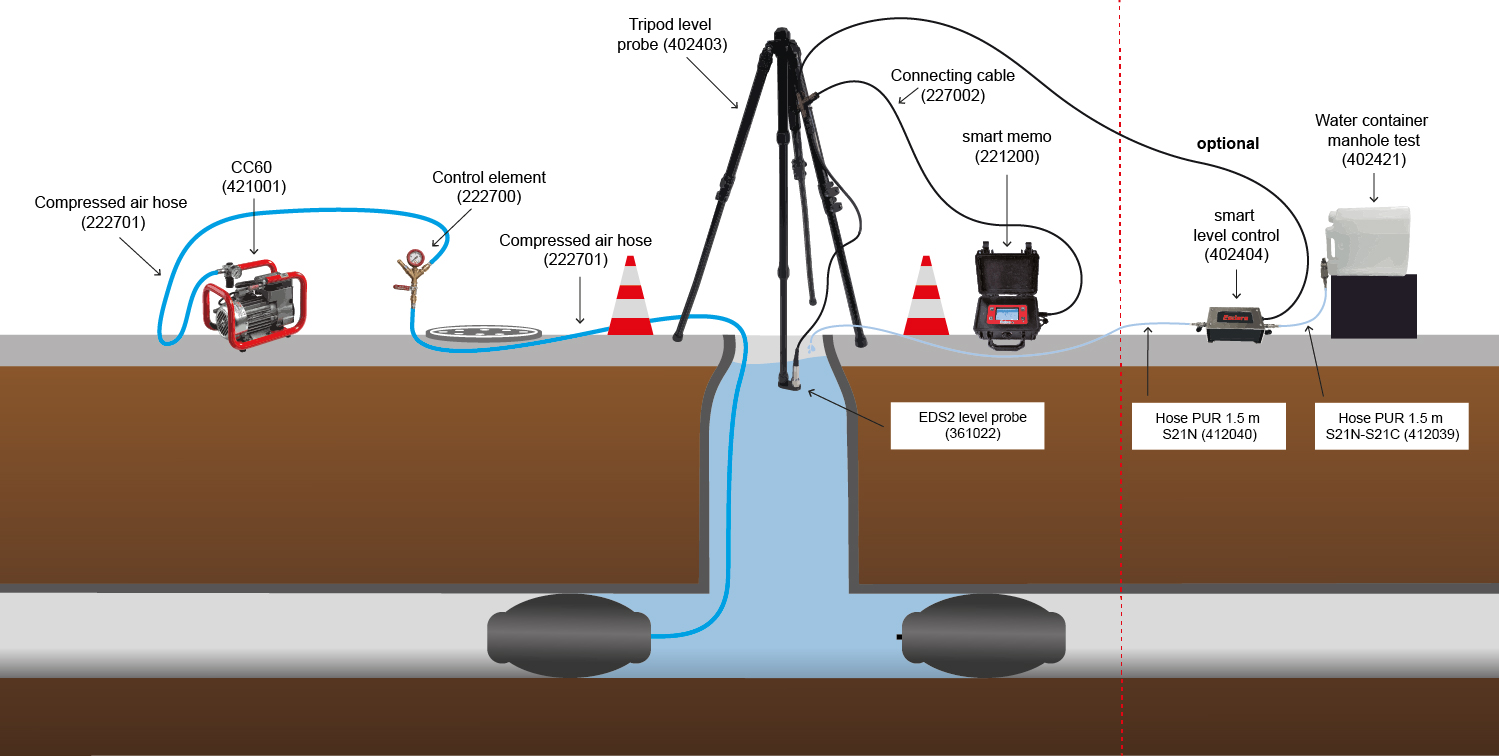

EDS2 Level Probe and Tripod Level Probe

An EDS2 level probe is required for the level measurement method. In addition, the level probe tripod is required for positioning above the test object, e.g. a manhole. The level probe can be screwed onto the tripod stand and, after the tripod stand has been successfully positioned, it is immersed in the test space using a telescopic mechanism. The depth of immersion should be selected so that it reaches approximately to the cable outlet on the level probe. A fixed connection cable is part of the level probe. It is connected to the T-connector B11, which is fixed to the tripod stand. The connection to the smart memo must then be established using an additional connection cable B11.

Automatic restoration of water level

We offer smart level control as an additional module for carrying out the leak test using the level measurement method. To avoid errors during the test and to automate the test, the water level is maintained or restored automatically during the test when using smart level control. As soon as the level drops below a specified limit, the water level is automatically restored. The water supplied is measured to an accuracy of 5 %. The measured value is automatically used for test evaluation and transferred to the test report.

The water tank level probe is required as a water reservoir for the smart level control. A suitable hose set is included with the smart level control.

Don’t miss any news about our products and new regulations!

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)